Table of Contents

Why Flexible PCBs Are Transforming Electronics

Flexible Printed Circuit Boards (FPCs) are reshaping the electronics industry with their lightweight, durable, and adaptable designs. From enabling sleek smartphones to powering advanced automotive systems, flexible PCBs deliver high-density wiring and dynamic flexibility for modern applications. At JHYPCB, we specialize in flexible PCB manufacturing and PCB assembly services, offering customized solutions for industries worldwide. Discover the top 8 uses of flexible PCBs and how they drive innovation. Contact us at sales@pcbjhy.com to start your project!

What Are Flexible PCBs? Definition and Key Benefits

Flexible PCBs are thin, lightweight circuits made from flexible substrates, allowing them to bend, fold, and fit into compact spaces. Unlike rigid PCBs, they offer high wiring density, reduced weight, and dynamic bending capabilities, making them ideal for miniaturized and mobile electronics.

Key Benefits of Flexible PCBs

- Compact Design: Reduces electronic product volume by 40-60% and weight by 50-80% compared to traditional components.

- High Reliability: Strong earthquake resistance and low solder joint defect rate ensure durability.

- Flexibility: Withstands millions of dynamic bends without damaging wires, perfect for moving parts.

- Reduced Interference: Minimizes electromagnetic and radio frequency interference for better performance.

- Efficient Assembly: Surface Mount Technology (SMT) enables high-density, automated assembly, saving time and costs.

At JHYPCB, our flexible PCB manufacturing and SMT assembly services ensure precision and reliability for your projects.

Top 8 Uses of Flexible PCBs

Flexible PCBs are integral to modern electronics, powering devices across industries. Below are the top 8 applications driving their demand.

1. Smartphones and Wearables

Flexible PCBs are the backbone of smartphones and wearables, enabling compact designs for hinges, camera modules, displays, and antennas. Modern smartphones use 5-12 FPCs, compared to 1-5 in feature phones, supporting dynamic bending in folding or sliding designs. For example, flexible PCBs in smartwatches allow lightweight, curved displays. JHYPCB provides multi-layer flexible PCB manufacturing to meet the high-density needs of consumer electronics.

2. Automotive Electronics

Flexible PCBs power automotive dashboards, sensors, and infotainment systems, fitting into the complex, three-dimensional structures of vehicles. In 2024, China’s automotive PCB market grew by 10.15% (China Association of Automobile Manufacturers), driven by demand for lightweight, reliable components. JHYPCB’s SMT and turnkey PCB assembly services deliver durable solutions for automotive applications.

3. Medical Devices

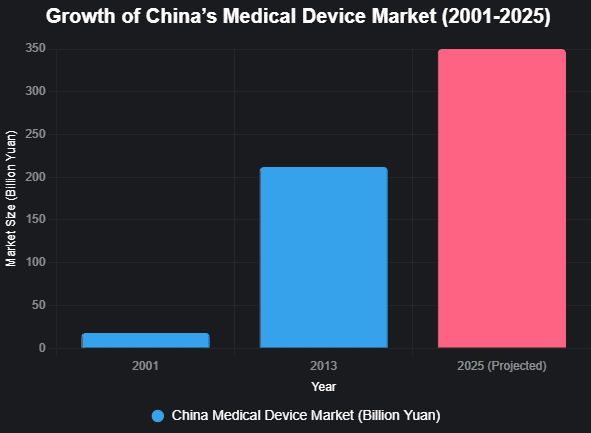

Flexible PCBs enable portable and lightweight medical devices, such as monitoring equipment and wearable health trackers. From 2001 to 2013, China’s medical device market grew from 17.9 billion yuan to 212 billion yuan, a 11.84x increase, with flexible PCBs reducing device weight by 50-80%. JHYPCB’s precision flexible PCB manufacturing supports cutting-edge medical innovations.

4. Consumer Electronics

From laptops to gaming consoles, flexible PCBs reduce size and weight while maintaining performance. They are used in LCD modules, buttons, and battery connections, supporting compact and durable designs. JHYPCB offers turnkey PCB assembly for seamless integration in consumer electronics.

5. Communication Devices

Flexible PCBs are critical in 5G devices, antennas, and USB cables, enabling high-speed signal transmission. Their flexibility ensures reliable connections in compact communication systems. JHYPCB’s _

SMT services ensure high-frequency performance for communication applications.

6. Aerospace and Defense

In aerospace, flexible PCBs are used in avionics and satellite systems, where lightweight and reliable circuits are essential. Their ability to withstand vibration and fit into tight spaces makes them ideal for high-reliability applications. JHYPCB provides multi-layer FPC solutions for aerospace needs.

7. Industrial Equipment

Flexible PCBs support sensors and control systems in industrial automation, offering durability in harsh environments. Their compact design optimizes space in complex machinery. JHYPCB’s PCB prototype services accelerate industrial innovation.

8. IoT Devices

The rise of IoT devices demands compact, flexible circuits for smart home systems, wearables, and sensors. Flexible PCBs enable seamless integration in space-constrained designs. JHYPCB’s component sourcing services ensure high-quality IoT solutions.

Flexible PCBs vs. Rigid PCBs: A Comparison

| Feature | Flexible PCBs | Rigid PCBs |

|---|---|---|

| Weight | 50-80% lighter than rigid PCBs | Heavier, less suited for compact designs |

| Flexibility | Bends and folds, withstands dynamic stress | Rigid, limited to fixed shapes |

| Applications | Smartphones, wearables, automotive | Traditional electronics, larger systems |

| Wiring Density | High, supports miniaturization | Moderate, less compact |

| Cost | Higher for complex designs | Lower for standard applications |

JHYPCB’s expertise in flexible PCB manufacturing ensures you get the right solution for your project’s needs.

Why Choose JHYPCB for Flexible PCB Solutions?

At JHYPCB, we offer end-to-end PCB manufacturing and assembly services, including:

- Flexible PCB Manufacturing: From prototypes to multi-layer FPCs, we deliver high-density, reliable circuits.

- PCB Assembly: SMT, THT, and turnkey assembly for seamless integration.

- Component Sourcing: High-quality components for your flexible PCB projects.

- SMT Stencils: Precision stencils for efficient assembly.

Our ISO-certified processes and global supply chain ensure quality and reliability. Contact us at sales@pcbjhy.com for customized solutions!

Future Trends in Flexible PCB Technology

The flexible PCB market is poised for growth, driven by:

- 5G Technology: Demand for high-speed, compact circuits in 5G devices.

- IoT Expansion: Increasing use in smart devices and sensors.

- Medical Advancements: Growth in wearable and portable medical devices.

- Automotive Innovation: Electrification and autonomous driving boosting PCB demand.

The chart below illustrates the growth of China’s medical device market, a key driver for flexible PCB demand.

Conclusion

Flexible PCBs are shaping the future of electronics, from smartphones to medical devices and beyond. Their lightweight, durable, and adaptable designs make them indispensable for modern applications. At JHYPCB, we provide flexible PCB manufacturing, PCB assembly, and component sourcing to bring your projects to life. Ready to power your next innovation? Contact us at sales@pcbjhy.com for tailored solutions!