Table of Contents

Introduction

Printed Circuit Boards (PCBs) are the backbone of modern electronics, powering everything from smartphones to medical devices. Before launching into full-scale production, PCB prototype manufacturing serves as a critical step to ensure quality, performance, and reliability. Why is prototyping so essential? It allows designers and manufacturers to validate circuit designs, identify potential issues, and optimize for cost-effective mass production. By catching errors early, prototyping saves time, reduces costs, and ensures your product meets industry standards.

At JHYPCB, we specialize in fast-turn PCB prototype services, offering single-sided, double-sided, and multilayer PCB solutions tailored to your needs. Curious about how prototyping can elevate your project? Read on to discover its key benefits and why partnering with a reliable manufacturer like JHYPCB is your first step toward success. Contact us at sales@pcbjhy.com for a free quote today!

Validating Circuit Design and Manufacturability

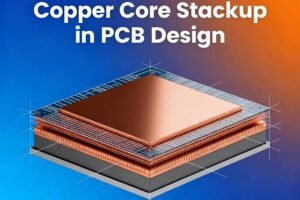

PCB design is a complex process, especially for multilayer boards like 8-layer, 10-layer, or even 12-layer configurations used in advanced electronics. Errors in design—such as incorrect trace widths, impedance mismatches, or thermal issues—can lead to costly rework or product failures. This is where PCB prototype manufacturing shines. Prototyping allows you to test and validate your circuit design and ensure it aligns with modern manufacturing capabilities before committing to mass production.

Through prototyping, you can perform critical tests like signal integrity analysis, thermal profiling, and Design for Manufacturability (DFM) checks. For example, a prototype might reveal a signal interference issue in a high-speed PCB, enabling you to adjust the layout early. A medical device client used prototyping to test a 10-layer PCB for a diagnostic tool, identifying a trace spacing issue that could have caused short circuits. After optimization, the design passed all tests, ensuring a reliable final product.

Reducing Defect Rates in Mass Production

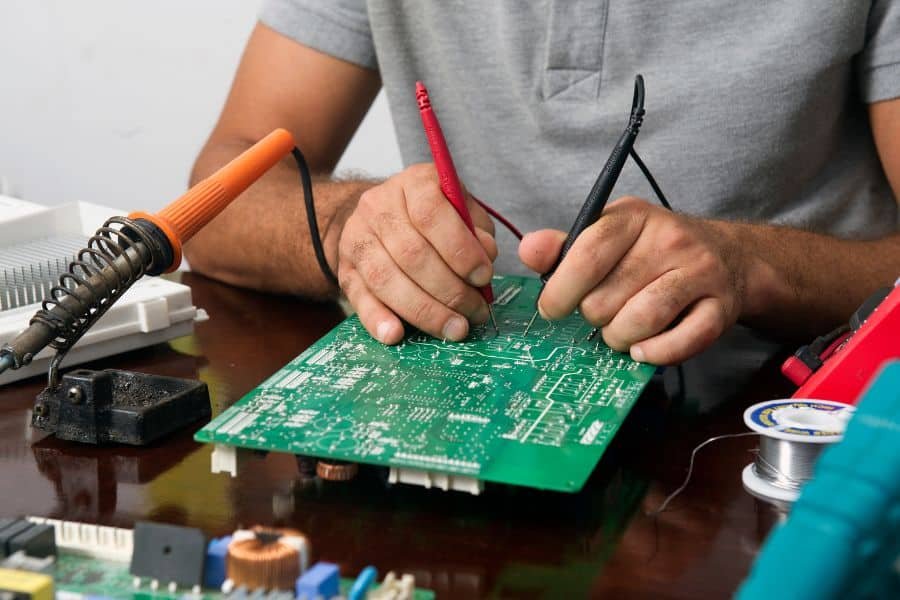

Mass production of PCBs involves intricate processes like etching, drilling, soldering, and assembly, where even minor errors can lead to significant quality issues. PCB prototype manufacturing plays a vital role in minimizing defect rates by identifying potential problems before full-scale production begins. By producing a small batch of prototypes, manufacturers can test for issues such as impedance mismatches, solder joint failures, or material defects, ensuring a smoother and more reliable production run.

Prototype testing typically includes rigorous evaluations like Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing. For instance, AOI can detect soldering imperfections, while ICT verifies electrical connectivity. Industry data shows that prototyping can reduce defect rates in mass production by 30-50%, saving significant costs and time. A consumer electronics company discovered a via alignment issue during prototype testing, preventing thousands of defective boards in production.

Assessing PCB Manufacturer Process Capability

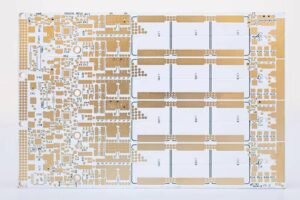

Selecting the right PCB manufacturer is crucial for ensuring high-quality printed circuit boards, especially for complex designs like high-density interconnect (HDI) boards or those using specialized materials. PCB prototype manufacturing offers a practical way to evaluate a manufacturer’s process capability before committing to large-scale production. By producing a small batch of prototypes, you can assess whether a manufacturer meets the technical demands of your project and delivers consistent quality.

Key factors to evaluate include the manufacturer’s ability to handle advanced processes, such as microvia drilling, controlled impedance, or high-frequency material fabrication. For example, a 12-layer HDI board requires precise layer alignment and reliable plating, which only manufacturers with advanced equipment can achieve. Prototyping also reveals a manufacturer’s turnaround time, adherence to industry standards (like ISO 9001 or IPC Class 3), and responsiveness to technical queries. A telecommunications client used prototyping to confirm a supplier’s ability to produce high-frequency PCBs with minimal signal loss, ensuring compliance with stringent performance requirements.

Laying the Foundation for Mass Production

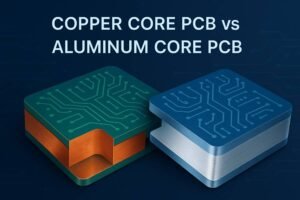

PCB prototype manufacturing is a critical step in preparing for efficient and cost-effective mass production. By producing and testing prototypes, you can evaluate a board’s performance, optimize material choices, and streamline manufacturing processes before scaling up. This proactive approach minimizes unexpected issues, such as supply chain delays or production bottlenecks, ensuring a seamless transition to full-scale production.

Prototyping allows you to assess functional performance under real-world conditions. For example, a prototype of an automotive PCB might reveal that a specific resin material improves thermal resistance, enhancing reliability in high-temperature environments. Additionally, prototyping helps calculate material costs and identify opportunities for savings. A consumer electronics firm adjusted its 8-layer PCB stack-up during prototyping, reducing laminate thickness and cutting material costs by 40% without compromising performance. These early optimizations ensure that mass production is both cost-efficient and reliable, delivering high-quality PCBs that meet project specifications.

Choosing the Right PCB Prototype Manufacturer

Selecting a reliable PCB prototype manufacturer is critical to ensuring your project’s success. The right partner can deliver high-quality prototypes that meet your design specifications and pave the way for seamless mass production. When evaluating manufacturers, focus on key factors such as technical expertise, production speed, quality certifications, and customer support.

- Technical Expertise: Ensure the manufacturer can handle complex designs, such as multilayer or HDI boards, and supports advanced processes like microvia drilling or high-frequency material fabrication.

- Production Speed: Fast-turn prototyping, ideally within 3-7 days, is essential for tight project timelines.

- Quality Certifications: Look for compliance with standards like ISO 9001 or IPC Class 2/3 to guarantee reliability.

- Customer Support: Responsive communication and detailed feedback during prototyping can prevent costly errors. For example, an aerospace company chose a manufacturer with IPC Class 3 certification for a 10-layer PCB prototype, ensuring compliance with stringent safety standards.

Conclusion: The Critical Role of PCB Prototyping

PCB prototype manufacturing is an indispensable step in the journey from design to mass production. By validating circuit designs, reducing defect rates, assessing manufacturer capabilities, optimizing for cost-effective production, and selecting the right manufacturing partner, prototyping ensures that your PCBs meet stringent quality and performance standards. Whether you’re developing complex multilayer boards for telecommunications or reliable single-sided boards for consumer electronics, prototyping minimizes risks and enhances efficiency. This process not only safeguards your project’s success but also delivers significant cost savings by addressing issues early. Investing in high-quality PCB prototyping sets the foundation for reliable, high-performance electronics, empowering you to bring innovative products to market with confidence.

Related Posts:

- How To Buy Prototype PCB Boards?

- Fast Turn Prototype PCB Service

- Low-Cost PCB Prototype Fabrication

- The Cheapest PCB Prototype Manufacturer-Your Best Choice

- Turnkey Prototype PCB Assembly Services At a Low-Cost

- Multilayer PCB Board Introduction And Prototype Fabrication Service

- Low-cost Double-sided PCB Board Prototype Production service