Introduction to the PCB Assembly Process

Printed Circuit Board (PCB) assembly is the backbone of modern electronics, powering everything from smartphones and medical devices to automotive systems and industrial equipment. At JHYPCB, we specialize in delivering high-quality PCB assembly services, including prototype PCB assembly, low-cost PCB assembly, quick-turn PCB assembly, turnkey PCB assembly, lead-free PCB assembly, and SMT stencil fabrication. Whether you’re a designer creating innovative prototypes, a procurement professional sourcing reliable manufacturing solutions, a beginner exploring PCB technology, or a business seeking scalable production, understanding the PCB assembly process is essential to achieving your project goals.

PCB assembly (PCBA) transforms a bare circuit board into a functional electronic system by mounting and soldering electronic components onto it. This intricate process involves advanced techniques like Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology, tailored to meet diverse application needs. From rapid prototyping for startups to high-volume production for established manufacturers, JHYPCB offers comprehensive solutions that ensure precision, efficiency, and cost-effectiveness.

In this guide, we’ll walk you through the complete PCB assembly process, from design and component placement to testing and delivery. You’ll discover how JHYPCB’s state-of-the-art facilities, certified by RoHS, UL, and ISO, deliver quick turn PCB assembly for urgent projects, turnkey PCB assembly for end-to-end convenience, and lead-free PCB assembly for eco-friendly compliance. Whether you need a custom SMT stencil for precise solder paste application or a low-cost solution for high-volume orders, JHYPCB is your trusted partner. Let’s dive into the world of PCB assembly and explore how we bring your electronic designs to life.

PCB Assembly Process Tutorial

What is PCB Assembly?

Printed Circuit Board Assembly (PCBA) is the process of transforming a bare PCB into a functional electronic system by mounting and soldering electronic components onto its surface. A bare PCB consists of a non-conductive substrate with conductive traces, designed to form electrical pathways. In contrast, PCBA involves the precise placement and connection of components—such as resistors, capacitors, integrated circuits (ICs), and transformers—to create a complete, operational circuit used in devices like smartphones, medical equipment, or industrial systems.

Recommended reading

The PCBA process requires expertise in component placement and soldering techniques to ensure reliable electrical connections and optimal performance. Various methods, including Surface Mount Technology (SMT) and Through-Hole Technology (THT), are employed based on the design requirements. PCBA is critical for turning a conceptual circuit design into a practical product, making it a cornerstone of modern electronics manufacturing.

Related Reading: What is the difference between wave soldering and reflow soldering?

Types of PCB Assembly

PCB assembly employs different techniques to mount electronic components onto a printed circuit board, each suited to specific design requirements and applications. The three primary types of PCB assembly are Surface Mount Technology, Through-Hole Technology, and Mixed Technology. Each method offers unique advantages and is chosen based on factors like circuit complexity, durability needs, and production scale.

1. Surface Mount Technology (SMT)

Surface Mount Technology involves mounting components directly onto the surface of a PCB using solder paste. Unlike traditional methods, SMT eliminates the need for drilled holes, allowing for smaller, lighter, and more compact designs. Components, such as resistors, capacitors, and integrated circuits, are placed on contact pads and secured through reflow soldering, a process that melts solder paste to form reliable connections. SMT is highly automated, enabling high-speed production and precision, making it ideal for modern electronics like smartphones, medical devices, and consumer gadgets. Its advantages include reduced board size, higher component density, and lower production costs for large-scale manufacturing.

2. Through-Hole Technology (THT)

Through-Hole Technology, an older method, involves inserting component leads into pre-drilled holes on the PCB, which are then soldered on the opposite side to form connections. This technique is known for its robust mechanical bonds, offering high durability and resistance to heat and stress. THT is often used for components requiring strong physical connections, such as connectors or transformers, and is common in applications like industrial controls or simple devices like digital clocks. However, THT is less suited for multilayer PCBs due to the complexity of drilling and lower component density, making it less efficient for high-volume production compared to SMT.

3. Mixed Technology

Mixed Technology combines SMT and THT to leverage the strengths of both methods. This approach is used in complex circuits requiring diverse components, such as those in automotive electronics or aerospace systems. For example, a PCB may use SMT for compact, high-density components on one side and THT for mechanically robust components on the other. Mixed Technology allows flexibility in design, accommodating both modern, compact layouts and reliable, heavy-duty connections. It is particularly valuable for double-sided assemblies or specialized applications where performance and durability are critical.

Each assembly type serves distinct purposes, and selecting the right method depends on the PCB’s intended function, design constraints, and production goals. Understanding these options helps designers and manufacturers create reliable, efficient electronic products tailored to their needs.

Types of Soldering in PCB Assembly

Soldering is a critical step in PCB assembly, securing electronic components to the printed circuit board to form reliable electrical and mechanical connections. The choice of soldering method depends on the PCB assembly type (SMT, THT, or Mixed Technology), component requirements, and production scale. The three primary soldering techniques used in PCB assembly are manual soldering, wave soldering, and selective soldering, each with distinct applications and characteristics.

Manual Soldering

Manual soldering is the traditional method where a technician uses a soldering iron to attach components to the PCB. This technique is typically used for Through-Hole Technology (THT) components, where leads are inserted into pre-drilled holes and soldered on the opposite side. Manual soldering is precise but time-consuming, making it suitable for low-volume production, prototyping, or repairs. It is often employed for large or heat-sensitive components, such as transformers, that require careful handling. However, its reliance on skilled labor limits its efficiency in high-volume manufacturing.

Wave Soldering

Wave soldering is an automated process designed for THT assemblies. Components are placed in drilled holes, and the PCB is passed over a wave of molten solder, which contacts the board’s underside to bond the leads. This method is efficient for single-sided PCBs with high component density, commonly used in applications like industrial controls or consumer electronics. However, wave soldering is not suitable for double-sided PCBs, as the molten solder can damage surface-mounted components on the underside, requiring alternative methods for complex assemblies.

Selective Soldering

Selective soldering is a modern, precise technique used for mixed technology or double-sided PCBs. It applies solder only to specific areas, typically THT components, using a programmable nozzle or drop-jet fluxing system, often in an inert nitrogen environment to enhance joint quality. This method minimizes thermal stress on sensitive components and supports complex designs, such as those in automotive or aerospace electronics. Selective soldering balances automation and precision, making it ideal for high-reliability applications where both THT and SMT components are present.

Each soldering method plays a vital role in PCB assembly, with the choice depending on design complexity, component types, and production needs. Understanding these techniques helps ensure robust, high-quality connections tailored to specific electronic applications.

Preparation Before PCB Assembly

Before PCB assembly begins, thorough preparation is essential to ensure a smooth manufacturing process and a reliable final product. This stage focuses on designing the printed circuit board and conducting a Design for Manufacturability (DFM) check to identify and resolve potential issues. Proper preparation minimizes costly errors, optimizes production efficiency, and ensures the PCB meets functional and performance requirements.

PCB Design

The PCB design process starts with creating a schematic and layout using specialized software, such as Altium Designer or KiCad. The schematic defines the electrical connections between components, while the layout determines their physical placement on the board, including conductive traces and pads. Designers must consider factors like signal integrity, power distribution, and component spacing to meet the intended application’s needs, whether for consumer electronics, medical devices, or industrial systems. A well-executed design aligns with the chosen assembly type—Surface Mount Technology (SMT), Through-Hole Technology (THT), or Mixed Technology—and sets the foundation for successful assembly.

DFM Check

A Design for Manufacturability (DFM) check is a critical step where manufacturers review the PCB design to ensure it can be produced efficiently and reliably. This process involves analyzing the design for potential manufacturing challenges, such as incorrect pad sizes, insufficient clearances, or complex layer alignments. Common DFM checks include:

- Power and Ground Check: Verifies proper connections to prevent short circuits or power loss.

- Silkscreen Check: Ensures component labels and markings are clear and correctly placed.

- Solder Mask Check: Confirms the protective layer aligns with solder pads to avoid soldering issues.

- Drill Check: Validates hole sizes and placements for THT components or vias.

- Signal Check: Assesses trace routing to ensure signal integrity and minimize interference.

- Mixed Layer Check: Confirms alignment of layers in multilayer PCBs for complex designs.

By identifying errors early, the DFM check allows designers to revise the design before production, reducing costs and delays. For example, correcting a misaligned pad during the DFM stage is far less expensive than reworking a fully assembled PCB. This preparation ensures the design is optimized for the chosen assembly process, whether it involves automated SMT lines or manual THT soldering.

Effective preparation through meticulous design and DFM checks is crucial for producing high-quality PCBs that meet performance standards and manufacturing requirements.

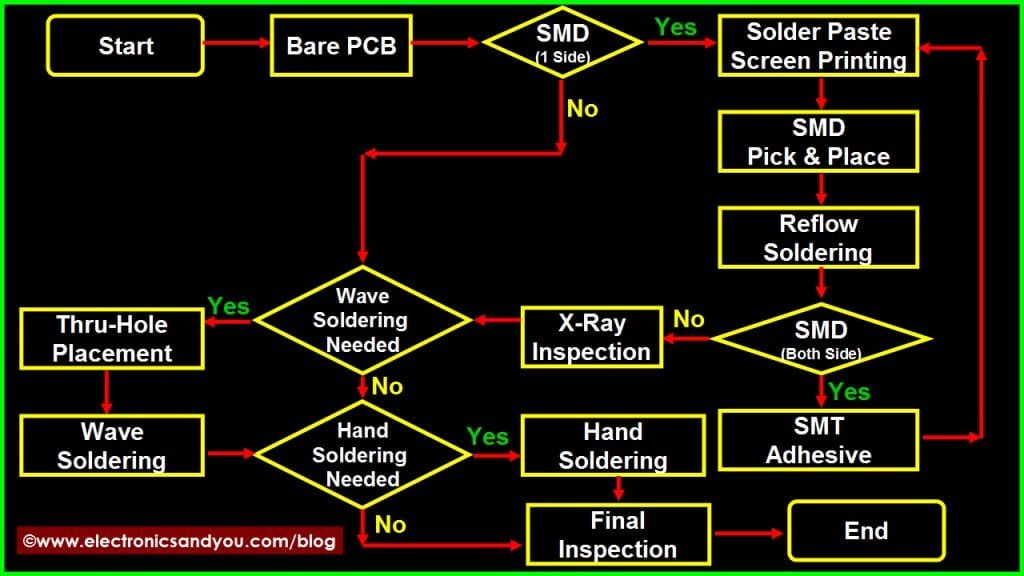

PCB Assembly Process

The PCB assembly process transforms a designed circuit board into a functional product through a series of precise, often automated steps. Each stage ensures components are accurately placed, securely connected, and thoroughly tested to meet performance and reliability standards. Below are the key steps involved in PCB assembly, applicable to Surface Mount Technology (SMT), Through-Hole Technology (THT), or Mixed Technology assemblies.

Step 1: Stencil Creation for Solder Paste Application

For SMT assemblies, a stainless steel stencil is created using laser cutting to match the PCB’s pad layout. The stencil ensures solder paste—a mixture of solder alloy and flux—is applied only to designated areas where components will be mounted. Precise stencil design is critical to control the volume and placement of solder paste, ensuring strong, reliable solder joints.

Step 2: Solder Paste Application

Solder paste is applied to the PCB’s contact pads using an automated screen printer. The printer aligns the stencil with the board, and a squeegee presses the paste through the stencil’s apertures. This step requires precision to avoid excess or insufficient paste, which could lead to defective solder joints. A 3D optical inspection system often verifies the paste’s volume and alignment.

Step 3: Component Placement

Automated pick-and-place machines position components, such as resistors, capacitors, or integrated circuits, onto the PCB. Using high-resolution cameras and pre-programmed coordinates, these machines ensure accurate placement on solder paste-covered pads. This step is highly efficient, enabling rapid assembly for high-volume production, particularly for SMT designs.

Step 4: Reflow Soldering

For SMT assemblies, the PCB is conveyed through a reflow oven with multiple temperature-controlled zones. The solder paste melts, bonding components to the board, then cools to form solid connections. The controlled heating and cooling process prevents thermal damage to components or the board, ensuring reliable solder joints.

Step 5: Optical Inspection

Automated Optical Inspection (AOI) uses cameras to examine the PCB for defects, such as missing components, misaligned parts, or solder bridging. AOI compares images of the assembled board against design specifications to ensure quality. While effective for surface-level issues, it cannot inspect solder joints beneath components, such as in Ball Grid Array (BGA) packages.

Step 6: Statistical Process Control

Statistical Process Control (SPC) analyzes quality data from the assembly process to identify trends and improve production. Software collects metrics, such as solder joint dimensions or component placement accuracy, enabling engineers to optimize processes and reduce defects. SPC enhances consistency across large production runs.

Step 7: X-Ray Inspection

For complex assemblies, such as those with BGA or Chip-Scale Package (CSP) components, X-ray inspection (AXI) examines hidden solder joints and internal PCB structures. X-rays detect voids, incomplete joints, or misaligned connections, ensuring high reliability in critical applications like aerospace or medical devices.

Step 8: Selective Soldering for THT Components

For THT or mixed technology assemblies, selective soldering applies solder to specific areas, typically component leads inserted through drilled holes. A programmable nozzle or drop-jet system delivers solder in an inert nitrogen environment, minimizing thermal stress and ensuring high-quality joints, especially for double-sided PCBs.

Step 9: Final Inspection and Handling

The assembled PCB undergoes final visual and functional inspections, often using stereo microscopes to verify solder joint quality and component alignment. Boards are cleaned to remove flux residues and packed in anti-static materials to prevent damage during shipping. This step ensures the PCB is ready for customer use.

Step 10: Feedback Collection

After delivery, manufacturers may collect customer feedback to identify issues and improve processes. This step, though not universal, helps refine production techniques and enhance product quality, ensuring the PCB meets performance expectations in real-world applications.

The PCB assembly process combines precision, automation, and rigorous testing to deliver reliable electronic products tailored to diverse design requirements.

Post-Assembly Processing

After PCB assembly, additional processing steps are necessary to ensure the board is clean, functional, and ready for delivery. These steps address residues left from soldering, verify performance, and prepare the PCB for its intended application. Proper post-assembly processing enhances reliability and improves the board’s appearance and longevity, critical for applications in consumer electronics, medical devices, or industrial systems.

PCB Cleaning

Soldering processes, particularly in Surface Mount Technology (SMT) and Through-Hole Technology (THT), often leave flux residues on the PCB. These residues, if not removed, can become sticky or acidic over time, potentially corroding solder joints or affecting electrical performance. To clean the PCB, deionized water is used to avoid introducing ions that could adhere to the circuit, unlike regular tap water. A high-pressure washer applies the deionized water to remove flux, dust, or other contaminants. After washing, compressed air dries the board quickly, ensuring no moisture remains that could compromise functionality. This step ensures the PCB is both visually appealing and reliable for end-use.

Functional Testing

Functional testing verifies that the assembled PCB performs as intended. This involves powering the board and running diagnostic tests to check electrical connectivity, signal integrity, and component functionality. Tests may simulate real-world operating conditions to ensure the PCB meets design specifications, such as those for automotive electronics or medical equipment. Any defects, such as faulty connections or incorrect component behavior, are identified and addressed, often through rework or redesign. Functional testing is critical to delivering a high-quality product that meets performance and reliability standards.

Packaging for Delivery

Once cleaned and tested, the PCB undergoes final preparation for delivery. Visual inspections, often using stereo microscopes, confirm solder joint quality and component alignment. The boards are then packaged in anti-static materials to protect against electrostatic discharge (ESD) during transport. Proper packaging ensures the PCB arrives at the customer in pristine condition, ready for integration into devices like smartphones or industrial controls. This step completes the assembly process, ensuring the product is both functional and professionally presented.

Post-assembly processing is essential for delivering a reliable, high-quality PCB that meets both technical and aesthetic standards, ensuring optimal performance in its intended application.

JHYPCB Assembly Services Overview

The PCB assembly process, as detailed in the previous sections, requires precision, expertise, and advanced technology to deliver reliable electronic products. JHYPCB, a trusted PCB manufacturing and assembly provider, offers comprehensive services tailored to diverse needs, from rapid prototyping to high-volume production. Our solutions support designers, engineers, and businesses in creating high-quality PCBs for applications in consumer electronics, medical devices, automotive systems, and more.

JHYPCB specializes in prototype PCB assembly, enabling rapid design validation for startups and innovators. Our quick turn PCB assembly service delivers fast turnaround times, ideal for time-sensitive projects. For end-to-end convenience, turnkey PCB assembly covers everything from component sourcing to final testing, streamlining the production process. We also provide low cost PCB assembly options, optimizing efficiency for large-scale orders without compromising quality. To meet environmental standards, our lead-free PCB assembly adheres to RoHS requirements, ensuring eco-friendly production. Additionally, JHYPCB offers SMT stencil fabrication, using high-precision laser cutting to support accurate solder paste application for Surface Mount Technology (SMT) assemblies.

Certified by RoHS, UL, and ISO, JHYPCB leverages state-of-the-art equipment and rigorous quality control to ensure every PCB meets industry standards. Whether you’re developing a prototype or scaling production, our services are designed to support your project’s success. For more details, contact our team to explore how we can bring your PCB designs to life.

Frequently Asked Questions (FAQs) About PCB Assembly

To help designers, engineers, and procurement professionals better understand PCB assembly, we’ve compiled answers to common questions about the process, technologies, and best practices. These insights clarify key concepts and address practical concerns in PCB manufacturing.

What is the difference between PCB and PCB assembly?

A Printed Circuit Board (PCB) is a bare board with conductive traces and pads, designed to form electrical pathways. PCB assembly (PCBA) is the process of mounting and soldering electronic components, like resistors or integrated circuits, onto the PCB to create a functional circuit. PCBA transforms a bare board into a ready-to-use product for applications like medical devices or consumer electronics.

What are the benefits of Surface Mount Technology (SMT) over Through-Hole Technology (THT)?

SMT allows for smaller, lighter PCBs with higher component density, ideal for compact devices like smartphones. It uses automated processes, reducing production time and costs. THT offers stronger mechanical bonds, suitable for durable components like connectors in industrial controls, but is less efficient for multilayer boards due to drilling requirements.

Why is a Design for Manufacturability (DFM) check important?

A DFM check reviews the PCB design to identify issues, such as incorrect pad sizes or poor trace routing, before assembly begins. This ensures the design is optimized for manufacturing, reducing errors, costs, and delays. For example, a DFM check can prevent soldering issues in prototype PCB assembly by verifying pad alignment.

What is the advantage of lead-free PCB assembly?

Lead-free PCB assembly uses solder alloys without lead, complying with environmental regulations like RoHS. It reduces environmental impact and meets global standards, making it essential for markets like Europe and North America. Lead-free processes maintain reliability while ensuring eco-friendly production.

How does quick turn PCB assembly work?

Quick turn PCB assembly prioritizes rapid production, often delivering boards within 24-48 hours. It’s ideal for time-sensitive projects, such as prototype PCB assembly for startups testing new designs. Automated processes, like pick-and-place and reflow soldering, enable fast, high-quality assembly without sacrificing precision.

What role does an SMT stencil play in PCB assembly?

An SMT stencil, typically laser-cut from stainless steel, ensures precise application of solder paste to PCB pads in SMT assembly. Accurate stencil design is critical for reliable solder joints, especially in high-density designs. It supports efficient, high-quality production for complex circuits.

Why is PCB cleaning necessary after assembly?

Cleaning removes flux residues, dust, or contaminants left from soldering. These residues can corrode solder joints or impair performance if left on the board. Using deionized water and compressed air ensures a clean, reliable PCB, ready for applications like automotive electronics.

What is turnkey PCB assembly?

Turnkey PCB assembly is a comprehensive service covering component sourcing, assembly, testing, and delivery. It simplifies the process for clients, allowing them to focus on design while the manufacturer handles all production stages. It’s ideal for businesses seeking efficient, end-to-end solutions.

These FAQs address key aspects of PCB assembly, helping you make informed decisions for your projects. For tailored solutions, contact a trusted provider like JHYPCB to explore options for your specific needs.

PCB Assembly Process Videos

Printed Circuit Board Assembly Process

SMT PCB Assembly Process | Surface Mount Technology Manufacturing Process

PCB Assembly Factory Tour (Full) – How To Assemble A PCB