Table of Contents

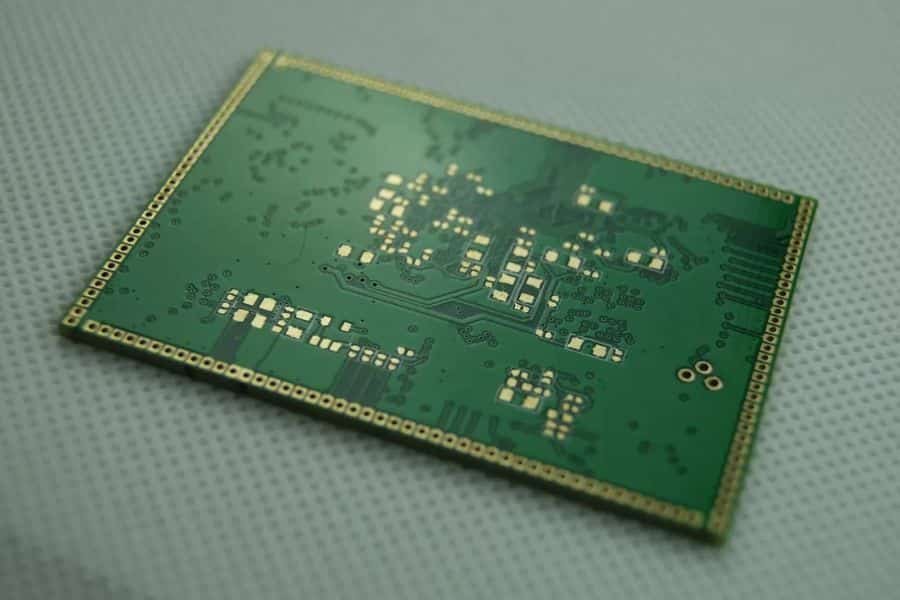

In today’s fast-evolving electronics industry, high Tg PCBs are essential for applications operating in extreme temperatures, such as automotive, aerospace, and industrial equipment. These printed circuit boards are designed to withstand temperatures above 170°C without losing structural integrity. Among various materials, FR4 stands out as the go-to choice for high Tg PCB manufacturing. But why is FR4 preferred over alternatives like metal or polyimide-based PCBs? At JHYPCB, we leverage FR4’s exceptional properties to deliver reliable, cost-effective, and high-performance PCBs tailored to your needs. In this article, we explore the key reasons behind FR4’s dominance in high Tg PCBs, from its thermal resilience to its affordability, and how JHYPCB ensures top-quality manufacturing for your projects. Ready to discover why FR4 is the ideal material for your high-temperature applications? Let’s dive in!

What is a High Tg PCB?

High Tg PCBs are specialized circuit boards designed to operate in high-temperature environments, typically above 170°C, without compromising structural integrity or performance. The term “Tg” refers to the glass transition temperature, a critical mechanical property that indicates the temperature at which a PCB material transitions from a rigid to a more flexible state. Choosing a PCB with a Tg value 20-25°C higher than the operating temperature is essential to prevent bending, warping, or performance degradation in demanding applications.

Glass Transition Temperature (Tg) Explained

The glass transition temperature (Tg) is a defining characteristic of PCB materials. When a PCB reaches its Tg, its substrate softens, potentially affecting electrical performance and mechanical stability. For standard PCBs, Tg values typically range from 130-140°C, but high Tg PCBs, such as those made with FR4, boast Tg values exceeding 170°C, with some reaching 200°C or higher. This makes them ideal for applications where thermal stress is a concern.

Applications of High Tg PCBs

High Tg PCBs are indispensable in industries requiring robust performance under elevated temperatures. Common applications include:

- Automotive Electronics: Engine control units and sensors exposed to high engine heat.

- Aerospace: Avionics and satellite systems operating in extreme thermal cycles.

- Industrial Equipment: Machinery and control systems in high-temperature manufacturing environments.

Telecommunications: Base stations and routers handling continuous high-power loads.

Why Choose FR4 for High Tg PCBs?

FR4 is the material of choice for high Tg PCBs due to its unique combination of electrical, mechanical, and thermal properties, making it ideal for high-temperature applications.

Excellent Electrical Performance

FR4 delivers exceptional electrical stability, ensuring consistent signal integrity even at temperatures exceeding 170°C. Its low dielectric constant and minimal signal loss make it perfect for high-frequency circuits and demanding environments.

Superior High-Temperature Resistance

High Tg FR4 PCBs are engineered to withstand temperatures above 170°C, with some variants supporting up to 200°C or higher without deforming. This thermal resilience ensures that the PCB retains its structural integrity under extreme conditions, such as in automotive engine control units or aerospace avionics. JHYPCB offers FR4 PCBs in low (130-140°C), medium (150-170°C), and high Tg (>170°C) ranges to meet diverse application needs.

Ideal for Plated Through-Hole (PTH) Components

FR4 excels in supporting plated through-hole (PTH) technology, offering superior reliability compared to metal-based PCBs. The material’s compatibility with PTH ensures secure component mounting, simplifying assembly processes for complex designs.

Precise Impedance Control

For applications requiring strict impedance control, FR4 is an excellent choice due to its stable dielectric properties. This ensures consistent signal transmission, critical for high-speed electronics like routers and base stations. JHYPCB’s expertise in FR4 PCB manufacturing guarantees precise impedance control, meeting the stringent requirements of modern circuit designs.

Durability and Longevity

FR4 is renowned for its robustness, resisting wear, tear, and thermal stress in harsh environments. Its shockproof nature ensures components remain intact, extending the lifespan of the PCB.

Cost-Effective Solution

Compared to alternatives like polyimide or metal-based PCBs, FR4 offers a cost-effective solution without compromising performance. Its affordability makes it accessible for a wide range of applications, from consumer electronics to industrial systems.

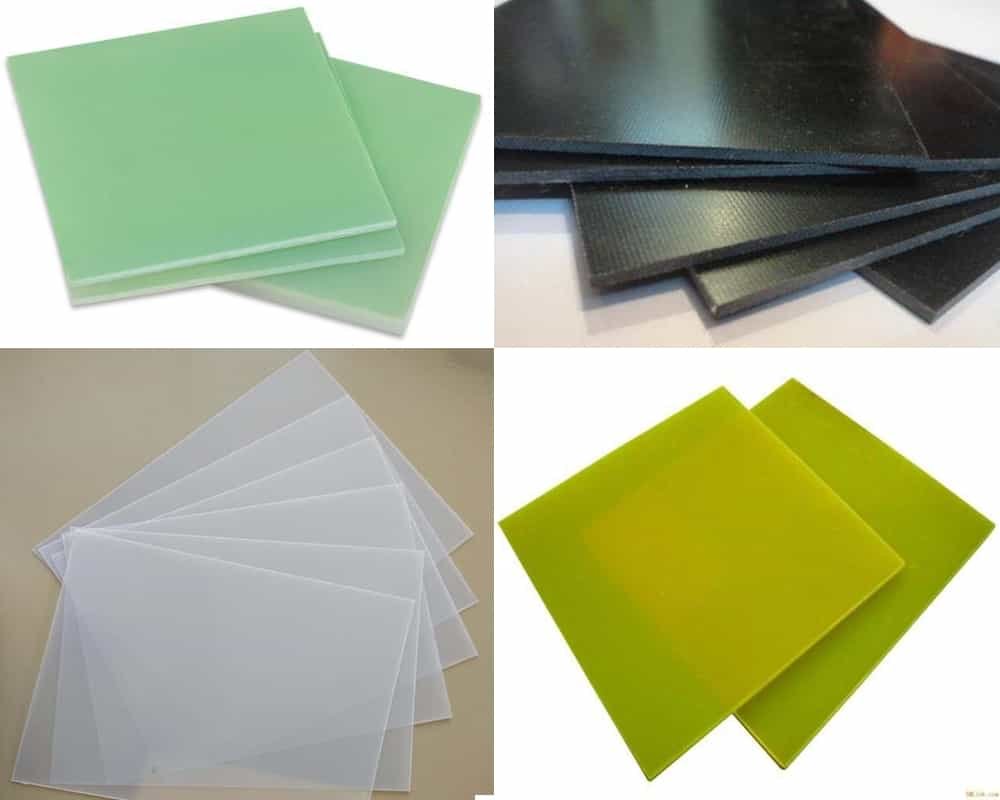

FR4 vs Other High Tg PCB Materials

When selecting materials for high Tg PCBs, FR4 is often compared to alternatives like polyimide, ceramic, and metal-based substrates. Each material has unique properties, but FR4 remains the preferred choice for many applications due to its balance of performance, cost, and versatility.

Comparison of FR4 with Polyimide, Ceramic, and Metal PCBs

The following table compares FR4 with polyimide, ceramic, and metal PCBs:

Material | Tg Range (°C) | Cost | Key Applications | Key Advantages |

|---|---|---|---|---|

FR4 | 130–200+ | Low | Automotive, Telecom | Cost-effective, reliable, versatile |

Polyimide | 200–300+ | High | Aerospace, Military | High Tg, flexible, thermally stable |

Ceramic | 250–400+ | Very High | High-power electronics | High thermal conductivity, high Tg |

Metal | N/A (No Tg) | Moderate | LED, Power electronics | Excellent heat dissipation |

Why FR4 Stands Out

- Cost-Effectiveness: FR4 is significantly more affordable than polyimide or ceramic, making it ideal for budget-conscious projects without sacrificing performance. JHYPCB’s FR4 high Tg PCBs offer a cost-effective solution for high-temperature applications.

- Versatility: FR4 supports a wide Tg range (130–200°C+), suitable for diverse applications, from consumer electronics to industrial systems.

- Ease of Manufacturing: Unlike ceramic or metal PCBs, FR4 is easier to process, especially for plated through-hole (PTH) components, ensuring reliable assembly. JHYPCB’s advanced manufacturing ensures precision and quality.

- Balanced Performance: While polyimide and ceramic offer higher Tg values, FR4 provides a robust balance of electrical performance, thermal resistance, and durability for most high Tg PCB needs.

For applications requiring extreme thermal conductivity, metal or ceramic PCBs may be considered, but for most high-temperature environments, FR4 high Tg PCBs deliver unmatched value and reliability.

JHYPCB’s FR4 High Tg PCB Manufacturing Services

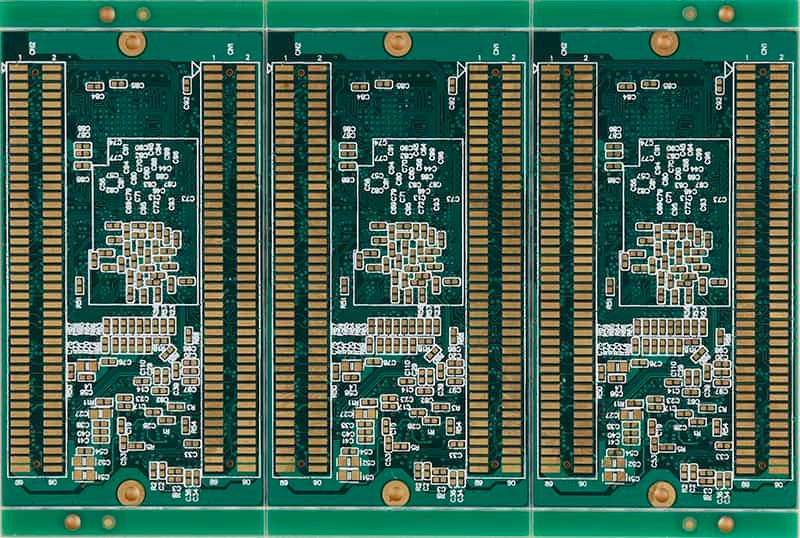

At JHYPCB, we specialize in manufacturing high-quality FR4 high Tg PCBs tailored to meet the demands of high-temperature applications in industries such as automotive, aerospace, telecommunications, and industrial electronics. Our advanced manufacturing capabilities, rigorous quality standards, and commitment to customer satisfaction make us a trusted partner for reliable and cost-effective PCB solutions. Discover how JHYPCB leverages FR4’s exceptional properties to deliver durable, high-performance PCBs for your projects.

Customized High Tg PCB Solutions

JHYPCB offers customized FR4 high Tg PCBs with Tg values ranging from 130°C to over 200°C, ensuring optimal performance in extreme thermal environments. Whether you need single-layer, multilayer, or complex designs with precise impedance control, our team works closely with you to meet specific requirements. From automotive engine control units to aerospace avionics, our FR4 high Tg PCBs are engineered for reliability and longevity.

Advanced Manufacturing and Quality Assurance

Our state-of-the-art facilities and strict quality control processes ensure every FR4 high Tg PCB meets industry standards, including ISO 9001 and UL certifications. We utilize advanced techniques for plated through-hole (PTH) assembly and impedance control, guaranteeing superior electrical and mechanical performance. JHYPCB’s commitment to quality ensures your PCBs withstand thermal stress and harsh conditions without compromising functionality.

Fast Turnaround and Competitive Pricing

JHYPCB combines rapid production with cost-effective solutions, making FR4 high Tg PCBs accessible for projects of all sizes. Our streamlined processes and global supply chain enable fast turnaround times without sacrificing quality. Whether you’re prototyping or scaling production, JHYPCB delivers affordable, high-performance PCBs tailored to your needs.

Why Choose JHYPCB?

- Expertise: Decades of experience in FR4 high Tg PCB manufacturing.

- Customization: Tailored solutions for unique application requirements.

- Support: Dedicated customer service for design and technical assistance.

- Reliability: High-quality PCBs backed by industry certifications.

Ready to elevate your project with JHYPCB’s FR4 high Tg PCBs? Contact us today for a custom quote and experience our industry-leading manufacturing services.

High Tg PCB FAQ

To help you better understand high Tg PCBs and why FR4 is the preferred material, we’ve compiled answers to some of the most common questions.

What Are the Typical Applications of High Tg PCBs?

High Tg PCBs are essential for applications in high-temperature environments, such as automotive engine control units, aerospace avionics, telecommunications base stations, and industrial machinery. FR4 high Tg PCBs from JHYPCB ensure reliable performance in these demanding settings, with Tg values exceeding 170°C to prevent warping or failure.

How Do I Choose the Right Tg Value for My PCB?

The glass transition temperature (Tg) should be 20-25°C higher than the operating temperature of your application. For environments above 170°C, JHYPCB recommends FR4 high Tg PCBs with Tg values of 170–200°C or higher, ensuring durability and electrical stability.

Is FR4 Suitable for All High-Temperature Environments?

FR4 is ideal for most high-temperature applications due to its cost-effectiveness, electrical performance, and thermal resistance. However, for extreme heat dissipation needs (e.g., high-power LEDs), metal or ceramic PCBs may be considered.

Why Choose JHYPCB for FR4 High Tg PCBs?

JHYPCB provides customized FR4 high Tg PCBs with advanced manufacturing, strict quality control (ISO 9001, UL certified), and competitive pricing. Our fast turnaround and dedicated support ensure your project’s success. Contact us to discuss your high Tg PCB needs!

Conclusion

FR4 high Tg PCBs are the ideal choice for high-temperature applications, offering a perfect balance of electrical performance, thermal resistance, durability, and cost-effectiveness. With Tg values exceeding 170°C, FR4 ensures reliability in demanding environments like automotive, aerospace, and industrial electronics. Its versatility, ease of manufacturing for plated through-hole components, and precise impedance control make it a go-to material for engineers worldwide. Compared to alternatives like polyimide or ceramic, FR4 delivers unmatched value without compromising quality.

At JHYPCB, we specialize in crafting high-quality FR4 high Tg PCBs tailored to your specific needs. Our advanced manufacturing, ISO 9001 and UL certifications, and commitment to fast delivery ensure your projects succeed in even the harshest conditions. Whether you’re prototyping or scaling production, JHYPCB is your trusted partner for reliable, cost-effective high Tg PCB solutions. Ready to elevate your next project? Contact JHYPCB today for a custom quote and discover how our FR4 high Tg PCBs can power your innovation!