Table of Contents

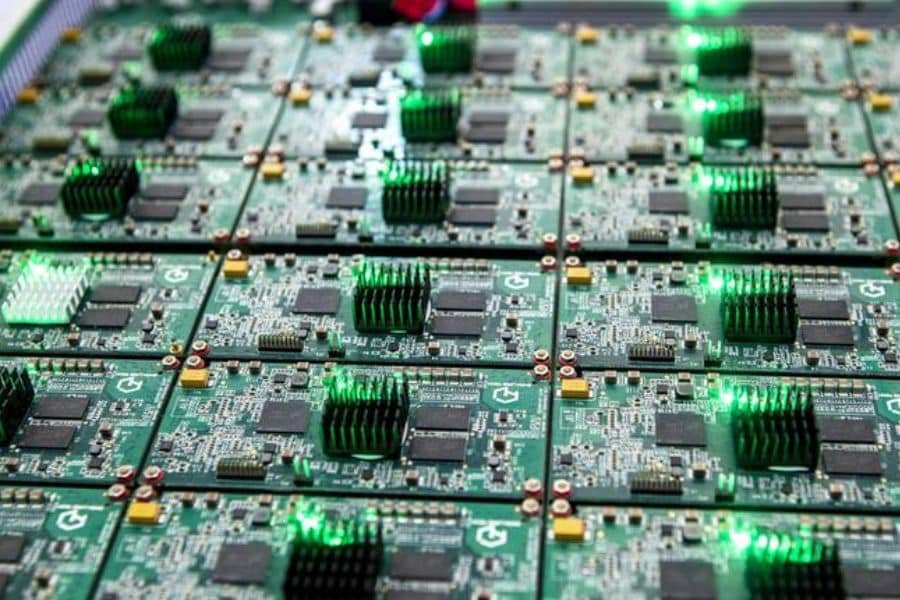

Printed Circuit Boards (PCBs) are critical components in electronic assemblies, acting as carriers for electronic signals. However, like any material, PCBs have a limited shelf life. Using an out-of-expiration PCB can lead to significant risks, impacting the reliability and performance of electronic products. This article explores the potential issues of using expired PCBs and provides guidance on how to manage them effectively.

Understanding the Role of PCBs in Electronics

PCBs serve as the backbone of electronic devices, enabling the transmission of electronic signals between components. For a PCB to function correctly, it must support effective soldering and maintain reliable contact points. If an expired PCB cannot withstand the soldering process or maintain signal integrity, it may lead to intermittent failures or complete dysfunction of the electronic product.

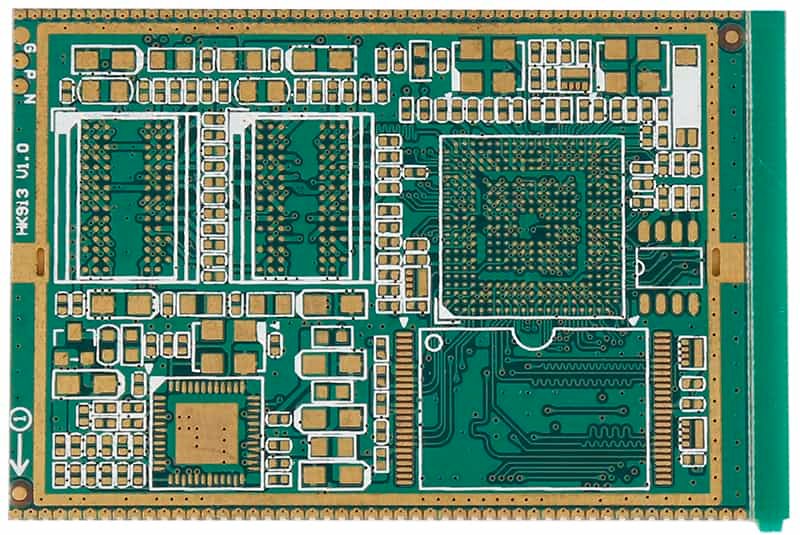

Modern PCB assembly typically involves soldering at high temperatures (240–250°C) to connect electronic components to the board. This process often requires double-sided soldering, meaning the PCB must endure high temperatures at least twice. Expired PCBs may struggle to withstand these conditions, leading to potential quality issues.

Key Risks of Using Expired PCBs

While not every expired PCB will fail, using them introduces several risks. Below are the primary concerns to watch for when considering out-of-expiration PCBs:

1. Oxidation of PCB Surface Pads

Expired PCBs are prone to oxidation on their surface pads, which can lead to poor soldering. Poor soldering increases the risk of functional failures or component detachment. The severity of oxidation depends on the PCB’s surface treatment:

- ENIG PCBs: Electroless Nickel Immersion Gold (ENIG) PCBs typically have a shelf life of 12 months. Beyond this period, oxidation may compromise solderability.

- OSP PCBs: Organic Solderability Preservative (OSP) PCBs have a shorter shelf life of about six months. Expired OSP PCBs may require reprocessing, which involves removing and reapplying the OSP film. However, this process risks damaging the copper foil circuit, so consult your PCB manufacturer before proceeding.

For ENIG PCBs, reprocessing is not an option. Instead, a “press bake” process can be used to test solderability, but this does not guarantee reliability.

2. Moisture Absorption and PCB Damage

Expired PCBs are more likely to absorb moisture, which can cause severe issues during soldering, such as:

- Popcorn Effect: Rapid heating during soldering can cause trapped moisture to expand, leading to cracks or delamination.

- Plate Explosion: Excessive moisture can cause the PCB to burst under high temperatures.

- Delamination: Moisture-induced stress can separate PCB layers, compromising structural integrity.

Baking can mitigate moisture issues, but not all PCBs are suitable for baking. For OSP PCBs, high-temperature baking may damage the protective film, requiring careful control of baking time and temperature. After baking, soldering must occur quickly to prevent re-oxidation of the pads.

3. Degradation of PCB Bonding Strength

Over time, the bonding strength between PCB layers may degrade, especially in expired boards. When subjected to high soldering temperatures, differences in thermal expansion coefficients among materials can cause:

- Delamination: Separation of PCB layers, which may break conductive vias and reduce electrical performance.

- Surface Bubbles: Trapped gases or moisture can create bubbles, affecting reliability.

- CAF (Conductive Anodic Filament): Micro-short circuits caused by degraded bonding, leading to intermittent issues that are difficult to diagnose.

These issues can severely impact the long-term reliability of the PCB, potentially causing failures in critical applications.

How to Manage Expired PCBs

To minimize risks when dealing with expired PCBs, consider the following steps:

- Check Shelf Life: Always adhere to the manufacturer’s recommended shelf life (e.g., 12 months for ENIG, 6 months for OSP).

- Consult the Manufacturer: For OSP PCBs, confirm with the PCB factory whether reprocessing is viable without damaging the board.

- Test Solderability: For ENIG PCBs, perform a press bake and test solderability before use.

- Control Moisture: Store PCBs in a dry, controlled environment and use humidity indicators to monitor conditions. If moisture absorption is suspected, bake the PCB only if suitable for the surface treatment.

- Inspect for Quality: Before using expired PCBs, inspect for signs of oxidation, delamination, or other defects.

Conclusion

Using out-of-expiration PCBs carries significant risks, including oxidation, poor soldering, moisture-related damage, and degraded bonding strength. These issues can lead to functional failures, reduced reliability, and intermittent problems in electronic products. To ensure quality, follow the manufacturer’s shelf life guidelines, store PCBs properly, and consult with your PCB supplier for reprocessing options. By taking these precautions, you can minimize risks and maintain the performance of your electronic assemblies.