Table of Contents

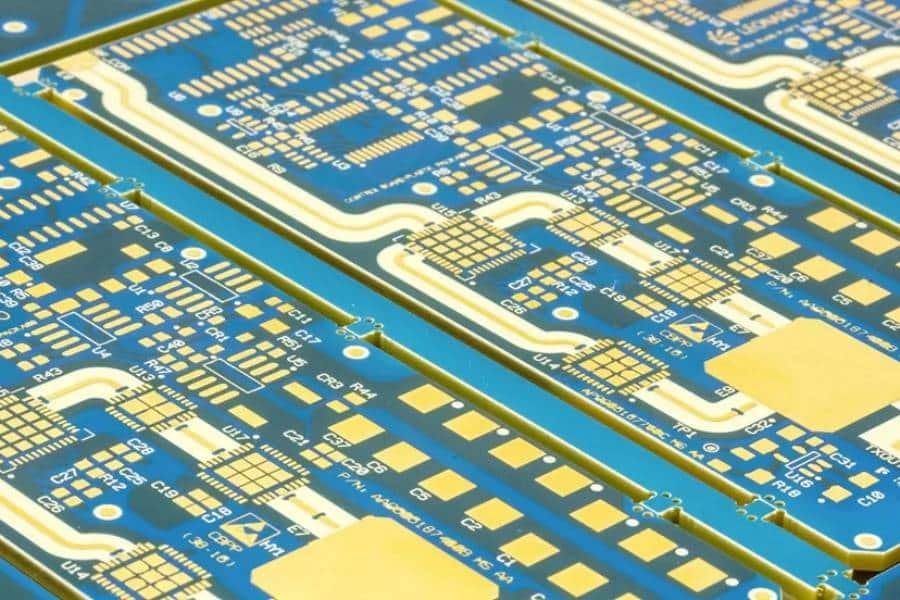

Rogers PCB materials, crafted by Rogers Corporation, are the gold standard for high-frequency and high-speed electronic applications. Renowned for their exceptional electrical, thermal, and mechanical properties, Rogers PCBs power cutting-edge technologies in telecommunications, automotive, aerospace, and defense. This comprehensive guide explores what Rogers PCB is, its key properties, types, benefits, applications, and comparisons with FR-4 and Teflon PCBs. Discover why Rogers PCB is the top choice for advanced electronics and connect with a trusted Rogers PCB Supplier for your next project.

What is Rogers PCB?

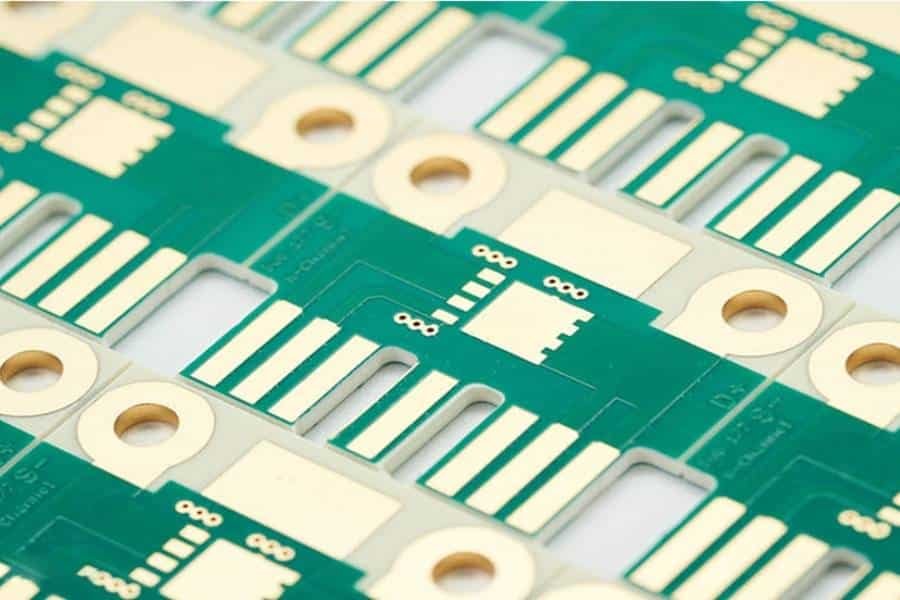

Rogers PCB refers to PCBs made with advanced laminate materials from Rogers Corporation. Unlike standard FR-4 PCBs, which rely on epoxy resin and glass fiber, Rogers laminates—such as PTFE (Teflon), ceramic-filled composites, or hydrocarbon blends—deliver superior performance in high-frequency environments. These materials are engineered for minimal signal loss, stable dielectric properties, and robust thermal management, making them ideal for applications like 5G antennas, radar systems, and microwave circuits.

For a deeper understanding of PCB technology, explore our PCB Manufacturing Services.

Key Properties of Rogers PCB Materials

Rogers PCB materials are designed for demanding applications. Their standout properties include:

- Low Dissipation Factor (Df): For example, RO4003C™ offers a Df of 0.0027 at 10 GHz, minimizing signal loss in high-frequency circuits.

- Stable Dielectric Constant (DK): Ranges from 2.2 to 10.2, ensuring consistent performance across broadband applications.

- Low Moisture Absorption: As low as 0.06% for RO4350B™, ensuring reliability in humid or extreme conditions.

- High Thermal Conductivity: Up to 0.69 W/m/K for RO4350B™, supporting efficient heat dissipation.

- Dimensional Stability: Maintains structural integrity across wide temperature ranges, critical for RF designs.

Types of Rogers PCB Materials

Rogers Corporation offers a diverse portfolio of materials tailored to specific needs. Below are the main categories:

Laminates

- RO4000® Series: High-frequency laminates with cost-effective fabrication. Examples include RO4003C™ (DK 3.38, used in automotive radar) and RO4350B™ (DK 3.48, ideal for 5G antennas).

- RO3000® Series: Ceramic-filled PTFE composites for microwave applications. Examples include RO3035™ (DK 3.50) and RO3210™ (DK 10.2), used in RF tags.

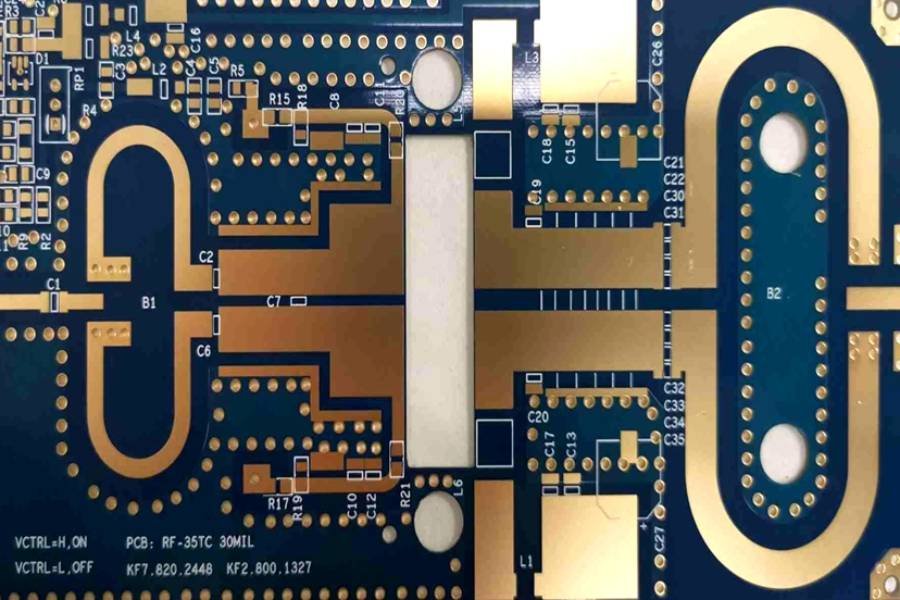

- RT/duroid® Series: Ultra-low-loss PTFE laminates like RT/duroid 5880 (DK 2.20) for aerospace and defense applications.

Bonding Materials

- Hydrocarbon/Ceramic Prepregs: Enable robust multilayer PCB construction.

- Thermoset Adhesive Films: Enhance thermal and electrical conductivity in RF designs.

- Ceramic PTFE Bondply: Ensures strong adhesion for high-frequency circuits.

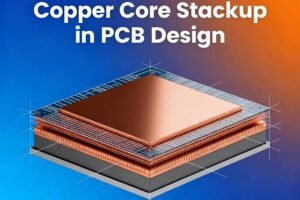

Metal Claddings

- Electrodeposited Copper: Provides uniform conductivity for precise signal transmission.

- Resistive Foil: Supports advanced impedance control.

- Reverse Treated Copper: Improves adhesion for complex multilayer designs.

For detailed specifications, visit Rogers Corporation.

Benefits of Rogers PCB

Rogers PCB materials offer significant advantages, making them a preferred choice for high-performance electronics:

- Superior High-Frequency Performance: Low Df (e.g., 0.0027 for RO4003C™) ensures minimal signal loss, ideal for 5G, microwave, and RF applications.

- Enhanced Thermal Management: High thermal conductivity prevents overheating in power-intensive devices like amplifiers and radar systems.

- Broad DK Range: Supports diverse applications, from antennas to satellite communications.

- Reliability in Harsh Environments: Low moisture absorption (e.g., 0.06% for RO4350B™) ensures performance in extreme conditions.

- Cost-Performance Balance: RO4000® Series offers high performance at a lower cost than pure PTFE laminates, balancing quality and affordability.

Applications of Rogers PCB

Rogers PCB materials are versatile, powering advanced technologies across multiple industries:

- Telecommunications: 5G base stations, antennas, and backhaul radios.

- Automotive: Radar sensors for autonomous vehicles and ADAS (Advanced Driver Assistance Systems).

- Aerospace and Defense: Satellite communications, radar systems, and RF identification tags.

- Medical: High-precision imaging and diagnostic equipment.

- Industrial: Automated test equipment and high-frequency power amplifiers.

| Industry | Application Example | Rogers Material |

|---|---|---|

| Telecommunications | 5G Antennas | RO4350B™ |

| Automotive | Radar Sensors | RO4003C™ |

| Aerospace | Satellite Communications | RT/duroid 5880 |

Comparing Rogers PCB with FR-4 and Teflon PCB

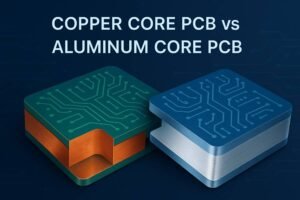

Rogers PCB vs. FR-4

| Feature | Rogers PCB | FR-4 PCB |

|---|---|---|

| Dielectric Constant | 2.2–10.2 | ~4.4–4.7 |

| Dissipation Factor | 0.0027 (10 GHz) | ~0.02 (10 GHz) |

| Thermal Conductivity | 0.69 W/m/K | ~0.3 W/m/K |

| Cost | $2–$15/unit | $0.5–$5/unit |

- Performance: Rogers PCB excels in high-frequency applications (up to 6 GHz) with lower signal loss and better impedance stability.

- Cost: Rogers PCB is pricier, but its performance justifies the investment for advanced designs.

- Applications: FR-4 suits general-purpose electronics, while Rogers PCB is ideal for RF and microwave circuits.

Rogers PCB vs. Teflon PCB

- Frequency Range: Rogers PCB supports up to 6 GHz, while Teflon PCB is typically limited to 5 GHz.

- Material Composition: Rogers offers ceramic-filled laminates for enhanced stability, unlike pure PTFE Teflon PCBs.

- Applications: Rogers PCB is suited for high-performance, high-cost designs; Teflon PCB is more cost-effective for simpler RF applications.

Choosing the Right Rogers PCB Supplier

Selecting a reliable supplier is critical for quality and performance. Key factors to consider include:

- Prototyping Services: Test materials like RO4350B™ or RO4003C™ for your specific application.

- Material Availability: Access to RO4000®, RO3000®, and RT/duroid® series.

- Certifications: Compliance with UL 94 V-0, IPC, and RoHS standards.

- Technical Support: Expert guidance on material selection and PCB design optimization.

FAQ: Your Questions About Rogers PCB Answered

Why choose Rogers PCB over FR-4?

Rogers PCB offers lower signal loss (Df 0.0027 vs. 0.02), a broader DK range (2.2–10.2 vs. ~4.5), and better thermal management, making it ideal for high-frequency applications.

What is the cost range for Rogers PCB?

Costs typically range from $2–$15 per unit, depending on the material and supplier. Get a custom quote for accurate pricing.

Which Rogers material is best for 5G applications?

RO4350B™ (DK 3.48, Df 0.0037) is widely used for 5G antennas due to its balance of performance, cost, and fabrication ease.

How does Rogers PCB handle extreme environments?

Low moisture absorption (e.g., 0.06% for RO4350B™) and high thermal conductivity ensure reliable performance in humid or high-temperature conditions.

Can Rogers PCB be used for multilayer designs?

Yes, bonding materials like hydrocarbon prepregs and adhesive films enable robust multilayer PCB construction.

Conclusion: Why Rogers PCB is the Future of Advanced Electronics

Rogers PCB materials redefine high-performance electronics with their low signal loss, stable dielectric properties, and exceptional thermal management. From 5G networks to aerospace radar, Rogers PCB outperforms FR-4 and Teflon PCB in demanding applications. Ready to elevate your project? Download our free Rogers PCB Material Guide or contact us for a custom prototype today!

Related Reading

- Unveil the mystery of high TG PCB circuit boards Materials

- Why choose FR4 as the general material of PCB?

- Why is FR4 Used to Make High Tg PCBs?

- What is the Tg value of PCB substrate?

- A Complete Introduction To Copper Clad Laminate (CCL)

- Complete Introduction of Flexible Circuit Board Materials

- A Comprehensive Comparison: Aluminum and FR4 PCBs