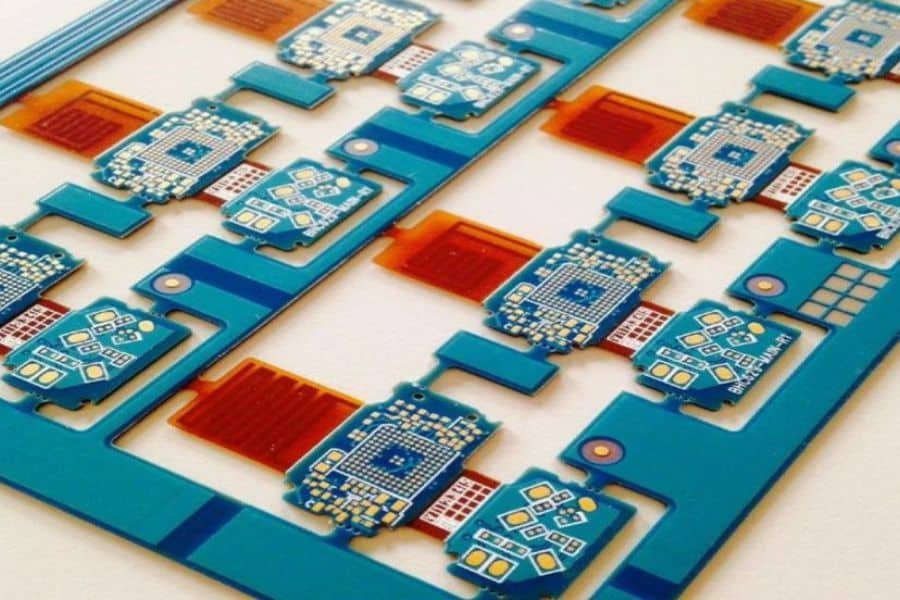

Introduction to Rigid-Flex PCBs

In today’s rapidly evolving electronics industry, the demand for compact, reliable, and versatile circuit boards is driving innovation. Rigid-flex PCBs, blending the flexibility of FPC (flexible printed circuits) with the durability of rigid PCBs, are at the heart of this transformation. As a leading rigid-flex PCB manufacturer with over 14 years of experience, JHYPCB delivers high-quality solutions for industries like medical, aerospace, and consumer electronics. This guide explores the rigid-flex PCB manufacturing steps, showcasing JHYPCB’s expertise in creating boards that power cutting-edge applications.

Why are rigid-flex PCBs so transformative? Unlike traditional rigid PCBs, limited by fixed geometries, or flexible circuits, which lack mechanical strength, rigid-flex PCBs offer a perfect balance. They eliminate bulky connectors, reduce weight, and enhance reliability in high-vibration environments. For instance, JHYPCB recently supported a medical device client by providing rigid-flex PCBs for a compact pacemaker, improving patient comfort while ensuring performance. Through advanced rigid-flex PCB manufacturing steps like LDI precision and UV laser cutting, JHYPCB delivers boards that meet the most demanding requirements.

Ready to discover how JHYPCB can bring your innovative designs to life? Contact us for a free consultation or keep reading to learn about the rigid-flex PCB manufacturing process.

What Are Rigid-Flex PCBs?

Rigid-flex PCBs are hybrid circuit boards that combine the flexibility of FPC (flexible printed circuits) with the structural stability of rigid PCBs. As a leading rigid-flex PCB manufacturer, JHYPCB leverages advanced materials and precision engineering to produce boards that meet the demands of complex rigid-flex PCB designs. These boards are ideal for applications requiring both bendability and durability, offering a compact, reliable solution for modern electronics.

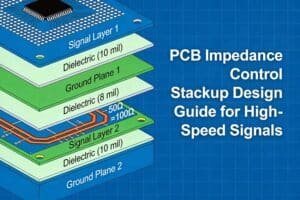

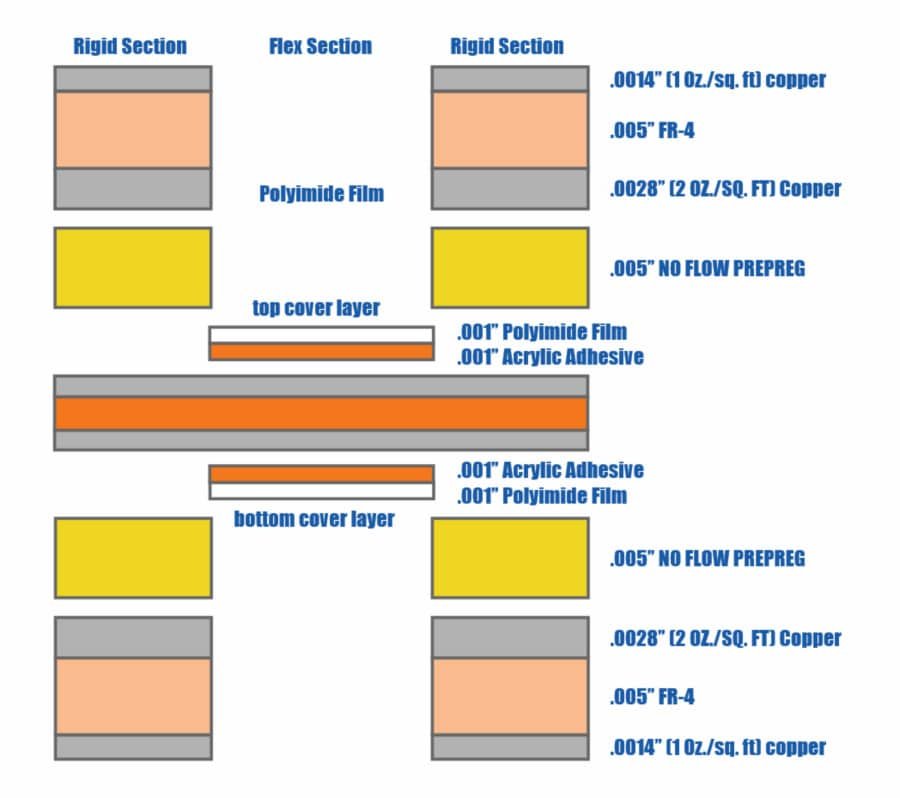

Structure of Rigid-Flex PCBs

A rigid-flex PCB comprises a flexible polyimide core, typically made from materials like DuPont Pyralux, sandwiched between rigid FR4 layers. These layers are bonded using prepreg, a glass-reinforced dielectric material cured under high temperature and pressure. The flexible core allows the board to bend in designated areas, while the rigid sections provide mechanical support for components. This hybrid structure eliminates the need for bulky connectors, streamlining rigid-flex PCB designs and reducing assembly complexity.

Key Materials in Rigid-Flex PCBs

The performance of rigid-flex PCBs depends on high-quality materials:

- Flexible Core: DuPont Pyralux FCCL (flexible copper-clad laminate) offers excellent thermal stability and flexibility, enabling reliable bending in dynamic applications.

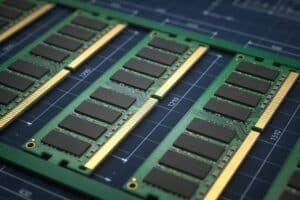

- Rigid Layers: FR4, a fiberglass-reinforced epoxy, provides durability and stability for mounting components.

- Prepreg and Coverlays: Prepreg bonds the layers, while coverlays protect the flexible copper surface, enhancing folding resistance.

JHYPCB selects premium materials to ensure optimal performance, tailoring each rigid-flex PCB design to meet specific application needs.

Design Advantages of Rigid-Flex PCBs

Rigid-flex PCBs offer several unique benefits:

- Space Efficiency: By integrating flexible and rigid sections, these boards reduce the need for connectors and cables, enabling compact designs.

- Enhanced Reliability: The flexible core absorbs mechanical stress, while rigid layers ensure stability, making them ideal for high-vibration environments.

- Lightweight Construction: Rigid-flex PCBs are lighter than traditional rigid boards, perfect for portable devices like wearables.

As a trusted rigid-flex PCB manufacturer, JHYPCB uses advanced LDI technology to achieve 30/30 µm trace width and spacing, ensuring precision in every board.

Want to learn how JHYPCB crafts these innovative boards? Keep reading to explore the rigid-flex PCB manufacturing steps or contact us for a free quote!

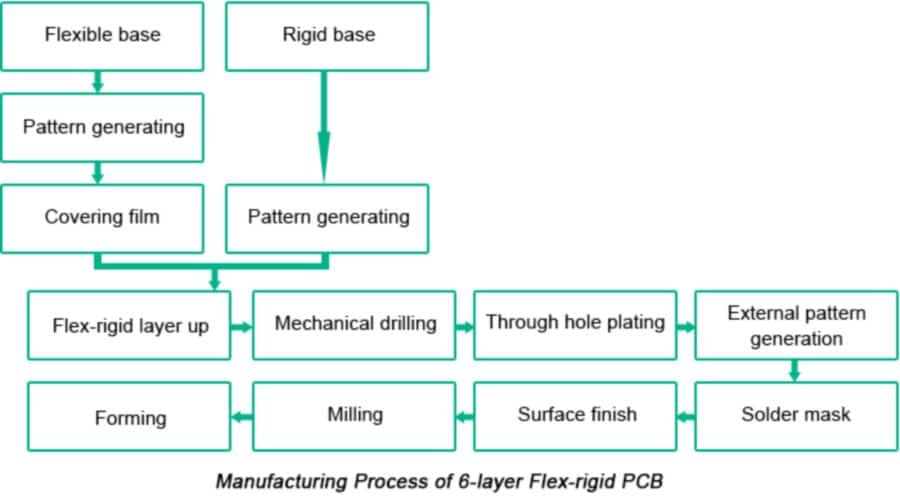

Rigid-Flex PCB Manufacturing Process

Producing rigid-flex PCBs is a complex, multi-step process that requires precision, advanced technology, and strict quality control. As a lead ing rigid-flex PCB manufacturer, JHYPCB employs state-of-the-art equipment and over 14 years of expertise to deliver boards that meet the stringent demands of industries like medical, aerospace, and automotive. The rigid-flex PCB manufacturing steps involve combining flexible and rigid layers into a single, reliable board. Below, we outline the 10 critical steps in JHYPCB’s rigid-flex PCB fabrication process, showcasing our commitment to quality and innovation.

Step 1. Material Preparation

The process begins with cutting high-quality materials to the required panel size. Flexible copper-clad laminates (FCCL), such as DuPont Pyralux, are used for the flex core, while FR4 is selected for rigid layers. Prepreg (glass-reinforced dielectric) and coverlays are also prepared. For rigid sections covering flex areas, copper foil is selectively removed to ensure bendability. JHYPCB’s precise material preparation ensures compatibility and durability in the final board.

Step 2. Drilling

Drilling creates vias and microvias for electrical connectivity between layers. JHYPCB uses mechanical drilling for standard through-holes and laser drilling for high-density interconnect (HDI) microvias, achieving apertures as small as 0.1 mm. Our advanced drilling systems minimize burrs and debris, ensuring clean, reliable vias critical for complex rigid-flex PCB designs.

Step 3. Circuit Generation

Circuit patterns are transferred onto the flex and rigid layers using photolithography. A dry film is applied, exposed to UV light, and developed to create the desired pattern. Acid etching then removes excess copper, leaving precise traces. For multi-layer flex cores (1–6 layers), JHYPCB laminates polyimide and rolled annealed copper, ensuring trace widths as fine as 30 µm for high-precision applications.

Step 4. Coverlay Lamination

A coverlay, typically polyimide-based, is applied to the flex core to protect the copper surface and enhance folding resistance. JHYPCB uses automated lamination systems to apply coverlays under controlled temperature and pressure, followed by automatic optical inspection (AOI) to detect any defects. This step ensures the flex sections remain durable in dynamic applications.

Step 5. Rigid Layer Lamination

Rigid FR4 layers are bonded to the flex core using prepreg under high temperature and pressure. JHYPCB’s advanced CCD hot melt equipment and automated laminating systems ensure precise alignment and strong adhesion. This step creates the hybrid structure, combining flexibility with mechanical stability, a hallmark of rigid-flex PCB fabrication.

Step 6. Black Hole Process

To enable electrical conductivity, JHYPCB applies a conductive carbon layer to via walls using the black hole method. This process metallizes the holes, preparing them for copper plating. Our proprietary approach ensures uniform carbon deposition, enhancing reliability across layers.

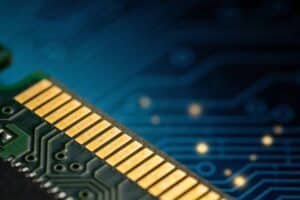

Step 7. Copper Plating

Vias are plated with a standard copper thickness (e.g., 1/3 oz to 3 oz for flex sections) to establish electrical connections between layers. JHYPCB’s controlled plating process ensures consistent thickness and signal integrity, critical for high-performance rigid-flex PCBs.

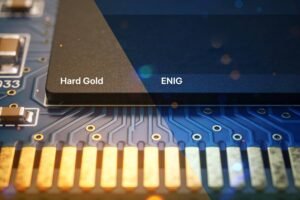

Step 8. Surface Finishing

A solder mask is applied to protect the board, followed by surface finishes like Electroless Nickel Immersion Gold (ENIG) or Hot Air Solder Leveling (HASL) to ensure solderability and prevent copper oxidation. Silkscreening adds labeling for assembly and traceability. JHYPCB’s rigorous AOI checks verify the integrity of this step.

Step 9. Opening Process

To create flexible sections, specific areas are removed using:

- UV Laser Depth Control: Precisely opens thin coverlays or core boards, achieving clean cuts with minimal thermal impact.

- Mechanical Routing: Forms closed paths for thicker openings, ensuring structural integrity.

- Mechanical Depth Control: Removes outer covers of thick sections for robust flex areas.

JHYPCB’s UV laser cutting technology enables rapid, precise openings, enhancing delivery times.

Step 10. Testing

Quality assurance is paramount. JHYPCB conducts:

- Automatic Optical Inspection (AOI): Detects circuit defects with high accuracy.

- Power-On Self-Tests: Verifies electrical functionality.

- Four-Terminal Sensing: Ensures minimal resistance tolerances for aerospace, medical, and automotive applications.

Our ISO9001-certified processes guarantee defect-free boards that meet industry standards.

As a trusted rigid-flex PCB manufacturer, JHYPCB’s advanced technologies, like LDI and UV cutting, ensure every step delivers precision and reliability. Curious about our capabilities? Explore our technical specifications or contact us for a free quote!

JHYPCB’s Rigid-Flex PCB Manufacturing Capabilities

As a premier rigid-flex PCB manufacturer, JHYPCB combines advanced technology with over 14 years of expertise to deliver high-quality boards for demanding applications. Our rigid-flex PCB capabilities enable us to support a wide range of industries, from medical devices to aerospace systems. With cutting-edge equipment and ISO9001-certified processes, we ensure precision, reliability, and fast delivery for both prototypes and bulk production. Below, we outline our manufacturing capabilities and highlight the technologies that set us apart.

Comprehensive Manufacturing Capabilities

JHYPCB offers a broad range of specifications to meet diverse design requirements. Our capabilities include:

| Parameter | Specification |

|---|---|

| Flex Section Layers | 1 to 6 |

| Rigid-Flex PCB Layers | 2 to 32 |

| Minimum PCB Size | 4 mm x 4 mm |

| Maximum PCB Size | 457 mm x 610 mm |

| PCB Thickness | 0.5 mm to 6 mm |

| Minimum Trace Width/Space | 30 µm / 30 µm (1.2 mil / 1.2 mil) |

| Through-Hole Size Tolerance | PTH: ±2 mil, NPTH: ±1 mil |

| Flex Section Copper Thickness | 1/3 oz to 3 oz |

| Rigid Section Copper Thickness | 1 oz to 6 oz |

| Minimum Mechanical Via Aperture | 0.15 mm |

| Minimum Laser Blind Via Aperture | 0.1 mm |

| Minimum PTH Via Pad Aperture | 0.35 mm |

| Minimum Blind Via Capture Pad Aperture | 0.25 mm |

| Minimum Prepreg Layer Thickness (Rigid Section) | 38 µm |

These specifications allow JHYPCB to produce rigid-flex PCBs for high-density interconnect (HDI) designs, ensuring compatibility with compact and complex applications.

Advanced Technologies That Set Us Apart

JHYPCB leverages state-of-the-art technologies to achieve superior precision and efficiency:

- Laser Direct Imaging (LDI): Our LDI technology enables trace widths and spacing as fine as 30 µm, ensuring high precision for intricate designs. This capability is ideal for applications requiring tight tolerances.

- UV Laser Cutting: JHYPCB uses UV laser cutting for precise opening processes, achieving clean cuts with minimal thermal impact. This technology accelerates production, enabling faster delivery times.

- Plasma Degumming: By applying plasma in a vacuum chamber, we enhance surface adhesion between flex and rigid layers, improving bonding strength and reliability.

- CCD Hot Melt Equipment: Our advanced laminating systems ensure accurate alignment during rigid layer lamination, reducing defects and ensuring consistent quality.

These technologies, combined with our rigorous quality control, make JHYPCB a trusted rigid-flex PCB manufacturer for industries requiring high-performance boards.

Interested in how our capabilities can support your project? Contact JHYPCB for a free quote or continue reading to explore the applications of rigid-flex PCBs!

Applications of Rigid-Flex PCBs

Rigid-flex PCBs have become indispensable in modern electronics, offering versatility and reliability across a wide range of industries. As of 2025, with the rapid advancement of smart devices and automation, the demand for these hybrid boards continues to grow. JHYPCB, a trusted partner in delivering innovative solutions, supports diverse applications with its expertise as a rigid-flex PCB manufacturer. This section explores the key industries benefiting from rigid-flex PCBs and highlights how JHYPCB meets their unique needs.

1. Rigid-Flex PCBs for Medical

In the medical field, rigid-flex PCBs enable compact and reliable devices critical for patient care. Applications include pacemakers, where their lightweight and flexible design reduces patient discomfort, and wearable health monitors that track vital signs in real-time. JHYPCB’s precision manufacturing ensures these devices meet stringent regulatory standards, supporting the latest 2025 innovations in telemedicine.

2. Rigid-Flex PCBs for Consumer Electronics

The consumer electronics industry relies on rigid-flex PCBs for sleek, portable devices. Smartwatches, VR headsets, and wireless earbuds benefit from their ability to fit into tight spaces while maintaining durability. In 2025, the rise of augmented reality (AR) glasses has further driven demand, with JHYPCB providing customized boards that enhance user comfort and performance.

3. Rigid-Flex PCBs for Automotive

In the automotive sector, rigid-flex PCBs are vital for smart, electric, and autonomous vehicles. They power control unit modules, sensors, and brake system plausibility devices, thriving in high-vibration and high-temperature environments. As of 2025, JHYPCB supports the growing trend of electric vehicle (EV) battery management systems with robust, flexible circuits tailored to automotive needs.

4. Rigid-Flex PCBs for Aerospace and Defense

Aerospace and defense applications demand lightweight, reliable solutions. Rigid-flex PCBs are used in satellite rotation axes, where their flexibility accommodates movement, and in weapon systems, reducing weight to optimize fuel efficiency. JHYPCB’s advanced fabrication techniques ensure these boards withstand extreme conditions, meeting 2025’s heightened aerospace standards.

5. Rigid-Flex PCBs for Industrial

In industrial settings, rigid-flex PCBs enhance equipment like CNC machines and stepper motors, where mechanical flexibility is essential. Their durability supports rotational movements and harsh environments, driving automation efficiency. JHYPCB’s expertise as a rigid-flex PCB manufacturer ensures these boards are tailored for industrial precision in 2025’s smart factory revolution.

JHYPCB’s Support for Diverse Applications

JHYPCB stands ready to support these industries with one-stop services, from design consultation to assembly. Our ability to customize rigid-flex PCBs for specific applications, backed by technologies like LDI and UV cutting, ensures optimal performance. Whether it’s a medical prototype or an aerospace component, JHYPCB delivers solutions that meet the latest 2025 industry demands.

Ready to explore how JHYPCB can enhance your next project? Contact us for a free quote or continue reading to learn why JHYPCB is your ideal partner!

Why Choose JHYPCB as Your Rigid-Flex PCB Manufacturer?

Selecting the right partner for rigid-flex PCB production is crucial for ensuring quality, reliability, and timely delivery. JHYPCB stands out as a trusted rigid-flex PCB manufacturer with a proven track record of excellence. With over 9 years of experience, advanced technologies, and a customer-first approach, we provide rigid-flex PCB solutions that meet the evolving demands of 2025’s fast-paced industries. Here’s why JHYPCB is your ideal choice.

1. Proven Experience in Rigid-Flex PCBs

With more than 14 years in PCB manufacturing and 10 years specializing in rigid-flex PCBs, JHYPCB has honed its expertise across diverse industries. From medical devices to aerospace components, our team has delivered thousands of successful projects, ensuring designs are both innovative and reliable.

2. Cutting-Edge Technology

JHYPCB leverages state-of-the-art equipment to achieve unparalleled precision:

- LDI Precision: Laser Direct Imaging ensures trace widths as fine as 30 µm, perfect for high-density designs.

- UV Laser Cutting: Enables rapid, precise openings, accelerating production timelines.

- Plasma Degumming: Enhances bonding strength between flex and rigid layers, ensuring durability.

These technologies enable us to deliver rigid-flex PCB services that meet the most stringent requirements.

3. Rigorous Quality Control

Quality is at the core of JHYPCB’s operations. Our ISO9001-certified processes include automatic optical inspection (AOI), four-terminal sensing, and power-on self-tests to ensure defect-free boards. Every rigid-flex PCB undergoes strict quality checks, guaranteeing performance in critical applications.

4. One-Stop Service

JHYPCB offers a seamless experience, from design consultation to assembly. Whether you need a prototype or bulk production, our one-stop rigid-flex PCB solutions streamline the process, saving you time and resources. In 2025, as industries demand faster turnarounds, our UV cutting technology ensures quick delivery without compromising quality.

5. Exceptional Customer Support

At JHYPCB, we prioritize your success. Our team provides free design consultations to optimize your rigid-flex PCB designs for manufacturability. For example, a recent 2025 project with an automotive client saw JHYPCB reduce production costs by 15% through design optimization, all while meeting tight deadlines. We’re here to support you every step of the way.

Ready to partner with JHYPCB for your next rigid-flex PCB project? Contact us for a free consultation or keep reading to explore common questions about rigid-flex PCB manufacturing!

FAQs About Rigid-Flex PCB Manufacturing

Rigid-flex PCB manufacturing involves intricate processes and advanced technologies, making it a topic of interest for engineers and businesses alike. As of 2025, with the growing demand for faster delivery and innovative designs, understanding these boards’ production is more critical than ever. This FAQ section addresses common questions about rigid-flex PCB production, providing insights from JHYPCB’s expertise as a leading PCB partner. Explore the answers below to find the information you need.

What is the Rigid-Flex PCB Manufacturing Process?

The rigid-flex PCB manufacturing process combines flexible and rigid layers into a single board. It includes material preparation, drilling for vias, circuit generation via photolithography, lamination of flex and rigid sections, copper plating, surface finishing, and rigorous testing. JHYPCB’s process leverages UV laser cutting and LDI technology for precision, typically completed in 2-4 weeks.

What Materials Does JHYPCB Use?

JHYPCB uses high-quality materials like DuPont Pyralux for the flexible core, known for its thermal stability, and FR4 for rigid layers, offering durability. Prepreg and coverlays enhance bonding and protection. These materials are selected to ensure reliability in applications ranging from medical to aerospace.

Is Quick-Turn Delivery Available?

Yes, JHYPCB offers quick-turn rigid-flex PCB production with lead times as short as one week for urgent projects. Our UV laser cutting and automated lamination systems, optimized for 2025’s fast-paced market, enable rapid prototyping without sacrificing quality.

What Industries Use Rigid-Flex PCBs?

Rigid-flex PCBs are widely used in medical (e.g., pacemakers), consumer electronics (e.g., smartwatches), automotive (e.g., EV sensors), aerospace (e.g., satellite systems), and industrial (e.g., CNC machines) sectors. Their flexibility and reliability make them ideal for compact, high-performance devices.

How Is Manufacturing Quality Ensured?

JHYPCB ensures quality through ISO9001-certified processes, including automatic optical inspection (AOI), power-on self-tests, and four-terminal sensing for critical applications. Every board undergoes rigorous checks to meet 2025’s stringent industry standards.

Does JHYPCB Offer Design Support?

Yes, JHYPCB provides free design consultations to optimize your rigid-flex PCB production for manufacturability. Our engineers collaborate with clients to refine layouts, reducing costs and improving performance, as demonstrated in recent 2025 projects.

Have more questions about rigid-flex PCB manufacturing? Contact JHYPCB for expert assistance or continue reading for the conclusion!

Conclusion

Rigid-flex PCBs have revolutionized the electronics industry, offering a perfect blend of flexibility, durability, and compactness that meets the demands of 2025’s innovative designs. From medical devices to aerospace systems, these boards drive technological advancements across diverse sectors. JHYPCB, with over 14 years of expertise and cutting-edge technologies like LDI and UV laser cutting, stands as a leader in delivering rigid-flex PCB services tailored to your needs. Our ISO9001-certified processes, one-stop solutions, and dedicated customer support ensure every project succeeds, whether it’s a prototype or large-scale production.

As industries evolve in 2025, partnering with the right team is more critical than ever. JHYPCB’s rigid-flex PCB experts are here to bring your vision to life with precision and efficiency. Don’t miss the opportunity to leverage our advanced capabilities—get a free quote now, email us at sales@pcbjhy.com, or schedule a consultation to discuss your next project. Let’s shape the future of electronics together!

Related PCB Manufacturing Services

Related PCB Assembly Services

Related Posts

- Rigid PCB Fabrication Capability

- Flexible PCB Fabrication Capability

- PCB Fabrication Process step by step

- Double-Sided PCB Manufacturing Process

- Introduction to the aluminum PCB manufacturing process

- The Main PCB Assembly process Steps

- The Production Process and Specifications of PCB SMT stencil

- What Are The Advantages And Applications Of Rigid-Flex PCBs?