Table of Contents

Introduction

In today’s fast-evolving tech landscape, multilayer PCBs are the cornerstone of high-performance electronics, powering everything from smartphones to satellites. Why are these advanced circuit boards so critical? Their ability to pack complex functionality into compact, reliable designs makes them indispensable across industries like consumer electronics, medical devices, and aerospace. This article explores the fundamentals of multilayer PCBs, their key benefits, and their transformative applications in modern technology. Discover how JHYPCB’s multilayer PCB solutions can elevate your next project—read on to learn more!

What is a Multilayer PCB and How Does It Work?

A multilayer PCB is a sophisticated circuit board comprising three or more conductive copper layers, including signal layers, internal plane layers, silkscreen overlays, solder mask layers, and more. These layers are laminated together with prepreg (PP dielectric layers) and interconnected through vias, such as plated through holes, blind vias, or buried vias. This construction enables compact, high-density designs for complex electronic systems.

JHYPCB specializes in manufacturing multilayer PCBs with up to 64 layers, catering to industries requiring precision and performance. Learn more about our multilayer PCB fabrication process here.

Key Components of Multilayer PCBs

- Signal Layers: Transmit electrical signals across the board.

- Internal Plane Layers: Provide power and ground planes for stable performance.

- Vias: Enable electrical connections between layers, including through-hole, blind, and buried vias.

- Prepreg and Core: Insulating materials that bond layers together, ensuring durability.

Top Benefits of Multilayer PCBs for Modern Electronics

Multilayer PCBs offer unmatched advantages over single- or double-layer boards, making them the preferred choice for advanced applications:

Benefit | Description |

|---|---|

Compact Size | Enables smaller, high-density designs for devices like smartphones and IoT sensors. |

Lightweight | Reduces product weight, ideal for aerospace and wearable devices. |

High Reliability | Ensures consistent performance in harsh environments, such as medical equipment. |

Enhanced Durability | Withstands thermal and mechanical stress in industrial machinery. |

Increased Flexibility | Supports complex circuits with a single connection point, simplifying assembly. |

These benefits make multilayer PCBs essential for industries requiring high performance and reliability. Explore our multilayer PCB assembly services here.

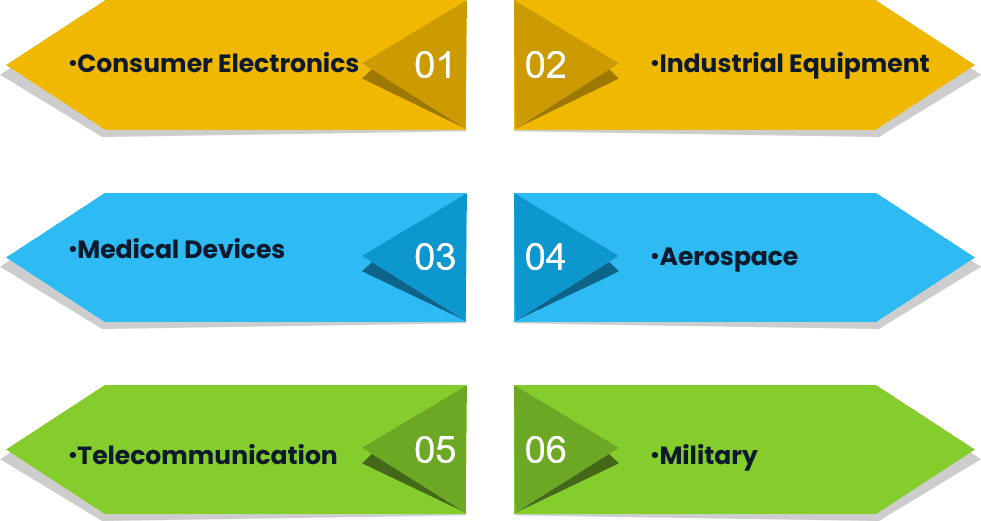

Industry Applications of Multilayer PCBs

Multilayer PCBs are integral to modern technology, powering devices across various sectors. Below are key applications:

Consumer Electronics: Powering Smartphones and Wearables

Multilayer PCBs are the backbone of consumer electronics, enabling compact, high-performance devices. For example, smartphones like the iPhone 14 or Samsung Galaxy S23 rely on multilayer PCBs with 10-12 layers to integrate 5G antennas, AI processors, and high-resolution cameras. Wearable devices, such as Apple Watch or Fitbit, use flexible multilayer PCBs for lightweight designs and reliable performance. These PCBs support high-speed signal transmission and efficient power management, critical for IoT devices and smart home systems.

Industrial Equipment: Driving Complex Machinery

Industrial machinery, such as robotic arms and CNC machines, requires multilayer PCBs to handle complex processes. For instance, high-density interconnect (HDI) multilayer PCBs are used in PCB manufacturing equipment to ensure precision and speed. These boards support advanced automation, enabling seamless operation in smart factories.

Medical Devices: Precision in Healthcare Technology

Multilayer PCBs are critical for medical equipment, from portable blood pressure monitors to advanced MRI machines. For example, ECG machines rely on multilayer PCBs with 8-10 layers to process high-frequency signals with precision. These boards ensure reliability in life-critical applications, meeting stringent medical standards.

Aerospace: Enabling High-Performance Systems

Aerospace applications, such as satellites and avionics systems, demand multilayer PCBs for their compact size and durability. For instance, satellite communication systems use HDI multilayer PCBs to manage high-frequency signals in extreme environments. These boards power sensors, actuators, and controllers, ensuring mission-critical performance.

Telecommunications: Supporting High-Speed Connectivity

Telecommunication systems, including 5G base stations and GPS navigation devices, rely on multilayer PCBs for reliable signal transmission. HDI PCBs enable compact designs and high-frequency performance, critical for satellite communication and signal towers.

Military: Precision and Durability in Defense Systems

Military equipment, such as radar systems and unmanned vehicles, requires multilayer PCBs for accuracy and resilience. These boards support complex signal processing and withstand harsh conditions, ensuring high performance in defense applications.

Why Choose JHYPPCB for Multilayer PCB Solutions?

Multilayer PCBs have revolutionized industries by enabling compact, reliable, and high-performance electronics. JHYPCB offers end-to-end solutions, including multilayer rigid PCBs, flexible PCBs, and rigid-flex PCBs, with up to 64 layers. Our advanced manufacturing ensures precision and quality for your projects.

Ready to integrate multilayer PCBs into your next project? Contact JHYPCB at sales@pcbjhy.com for expert multilayer PCB fabrication and assembly services. Request a quote today with your Gerber files and BOM!

Frequently Asked Questions (FAQs)

What are the benefits of multilayer PCBs?

Multilayer PCBs offer compact size, lightweight design, high reliability, and enhanced performance for complex applications like smartphones, medical devices, and aerospace systems.

How are multilayer PCBs used in consumer electronics?

They enable high-density designs for devices like smartphones, wearables, and IoT systems, supporting 5G connectivity, AI processors, and advanced sensors.

Why are multilayer PCBs essential for medical devices?

They provide precision and reliability for equipment like ECG and MRI machines, ensuring accurate signal processing in life-critical applications.

How can I get started with multilayer PCB fabrication?

Contact JHYPPCB at sales@pcbjhy.com with your Gerber files and BOM for customized multilayer PCB solutions.

Explore more about our flexible PCB solutions here or request a consultation today!

Related Posts

- Single-Layer PCB Vs. Double-Sided PCB: How To Choose?

- Quality Control of Engineering Data for Multilayer PCB

- Angle Control in Multilayer PCB

- What is a Multilayer PCB and What are the Advantages?

- What is Via Hole in Multilayer PCB?

- Standard PCB Thickness—All You Need To Know

- Guide to Multilayer PCB Layer Stackup and thickness