Table of Contents

Introduction to PCB Prototypes

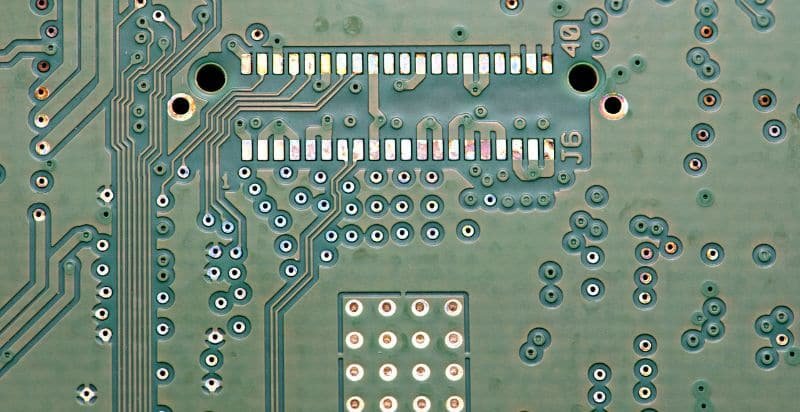

PCB prototypes are critical in developing electronic devices, allowing engineers to test and refine designs before mass production. This guide explores the essentials of PCB prototype manufacturing, including the process, types, and key considerations for selecting a manufacturer. Whether you’re an engineer or a business owner, understanding PCB prototyping ensures your projects meet quality standards and deadlines. JHYPCB, a leading PCB prototype manufacturer, offers high-quality, cost-effective solutions tailored to your needs.

What is a PCB Prototype?

A PCB prototype is a preliminary version of a circuit board used to validate design functionality before full-scale production. By identifying design flaws early, prototypes save time and costs while ensuring the final product meets performance standards.

PCBs consist of copper foil layers laminated onto a substrate, etched to form conductive pathways connecting components like resistors, capacitors, and integrated circuits. Prototypes come in various types:

- Single-sided PCBs: Components and pathways on one side, ideal for simple circuits.

- Double-sided PCBs: Components on both sides, offering greater design flexibility.

- Multi-layered PCBs: Multiple layers of pathways and components, suitable for complex electronics.

Prototypes are essential for testing functionality, verifying design parameters, and troubleshooting errors, ensuring the final product aligns with specifications.

PCB Prototype Manufacturing Process

The PCB prototype manufacturing process involves several precise steps to transform a design into a functional board. Here’s an overview:

- Design: Engineers use CAD software to create a detailed PCB layout, specifying component placement and conductive pathways.

- Printing: The design is printed onto a photomask, a film used to transfer the layout onto the board during etching.

- Drilling: Precision equipment drills holes for component placement, ensuring accuracy for small vias.

- Plating: A copper layer is applied to the board, enhancing the durability of conductive pathways.

- Etching: Excess copper is removed using an acidic solution, leaving only the designed pathways.

- Soldering: Components are fused to the board by heating metal connections.

- Testing: The prototype undergoes functional, voltage, and temperature tests to verify performance.

- Assembly (Optional): For comprehensive testing, full assembly includes soldering components and final validation.

Each step requires precision to ensure the prototype meets design specifications. JHYPCB uses advanced equipment to deliver reliable results.

Factors to Consider When Choosing a PCB Prototype Manufacturer

Selecting the right PCB prototype manufacturer is crucial for project success. Consider these factors:

- Quality: Ensure the manufacturer uses high-quality materials and strict quality control to guarantee performance and durability.

- Experience and Expertise: Choose a provider with a proven track record, like JHYPCB, with years of industry experience.

- Turnaround Time: Fast delivery is critical for tight schedules. JHYPCB offers turnaround times as quick as 24 hours.

- Cost-Effectiveness: Balance cost and quality to avoid compromising on performance.

- Customization: Look for manufacturers offering tailored solutions to meet unique project requirements.

- Communication: Responsive customer support ensures your needs are met throughout the process.

Common Mistakes to Avoid:

- Prioritizing low cost over quality.

- Failing to verify the manufacturer’s expertise.

- Ignoring turnaround times and delivery schedules.

- Overlooking quality control processes.

JHYPCB’s PCB Prototype Services

JHYPCB, a trusted China-based manufacturer, offers comprehensive PCB prototype services designed for quality and efficiency. Key features include:

- Prototype Types: Single-sided, double-sided, and multi-layered PCBs to suit diverse projects.

- Surface Finishes: Options like HASL, ENIG, and OSP for optimal performance.

- Solder Masks: Multiple colors (green, black, red, white, blue, yellow) for customization.

- Fast Turnaround: Delivery in as little as 24 hours to meet tight deadlines.

- Quality Standards: Advanced testing ensures compliance with industry standards.

- Affordable Pricing: Competitive rates without compromising quality.

- Customer Support: Dedicated team for seamless project communication.

Frequently Asked Questions (FAQs)

What is the difference between single-sided and multi-layered PCBs?

Single-sided PCBs have components on one side, ideal for simple designs. Multi-layered PCBs feature multiple layers, supporting complex circuits with higher functionality.

How long does PCB prototype manufacturing take?

Turnaround times vary, but JHYPCB offers delivery in as little as 24 hours, depending on project complexity.

Why is quality control important in PCB prototyping?

Quality control ensures prototypes meet design specifications, preventing costly errors in mass production.

Can JHYPCB provide customized PCB prototypes?

Yes, JHYPCB offers tailored solutions to meet specific project requirements, including custom layouts and finishes.

Conclusion

PCB prototypes are vital for developing reliable electronic devices. By understanding the manufacturing process and choosing a trusted manufacturer like JHYPCB, you can ensure high-quality prototypes that meet your project’s needs. With fast turnaround times, competitive pricing, and excellent customer support, JHYPCB is your ideal partner for PCB prototyping.