Table of Contents

In today’s fast-paced world of electronics, where devices are getting smaller, smarter, and more powerful by the day, the humble printed circuit board has had to evolve right alongside them. Remember the bulky gadgets from a couple of decades ago? They relied on simple PCBs that got the job done without much fuss. But now, with everything from electric vehicles to 5G networks demanding top-notch performance, we need something more robust. That’s where advanced PCBs come into play.

If you’re an engineer, designer, or just someone curious about how modern tech works, you’ve probably heard the term “advanced PCB” thrown around. But what exactly is an advanced PCB? In simple terms, it’s a PCB that goes beyond the basics—think standard FR4 or aluminum boards—and incorporates specialized materials, complex layering, and enhanced features to handle high-speed signals, extreme temperatures, heavy currents, or tight spaces. These aren’t your everyday circuit boards; they’re engineered for demanding applications where reliability and efficiency are non-negotiable.

At JHYPCB, as a leading PCB manufacturer based in China, we’ve been crafting these high-performance wonders for over a decade. Our services cover everything from PCB fabrication—including prototypes, single-sided, double-sided, multilayer, rigid, flexible, and rigid-flex PCBs—to full PCB assembly like SMT, THT, mixed technology, turnkey assembly, component sourcing, and even SMT stencils. We’ve helped clients worldwide bring innovative products to life, and in this guide, we’ll break down what makes an advanced PCB tick. We’ll compare it to basic PCBs, dive into the different types, explore real-world applications, and explain why partnering with a reliable manufacturer like us can make all the difference. Let’s get started—whether you’re planning your next project or just expanding your knowledge, there’s something here for you.

Advanced PCB vs. Basic PCB: Key Differences

Before we jump into the nitty-gritty, it’s helpful to understand how advanced PCBs stack up against their basic counterparts. At the core, all PCBs serve the same purpose: providing a platform for electrical components to connect and function. But the devil is in the details, especially when your project pushes the limits.

Basic PCBs are typically single- or double-layer boards made from FR4 (a fiberglass-reinforced epoxy) or aluminum. They’re straightforward, cost-effective, and perfect for low-stakes applications like consumer toys, simple LED lighting, or general electronics. Think of them as the reliable workhorses—easy to produce, quick to assemble, and budget-friendly. For instance, if you’re building a basic remote control or a household gadget, a single-layer aluminum PCB might be all you need to dissipate a bit of heat and keep things running smoothly.

On the flip side, advanced PCBs are designed for the heavy lifting. They use high-performance materials like ceramics or PTFE (Teflon), boast multiple layers (sometimes 40 or more), and incorporate intricate features such as microvias or embedded components. These boards excel in areas where basic ones fall short: handling high currents, managing intense heat, supporting high-speed data transmission, or fitting into ultra-compact designs. The result? Greater miniaturization, improved signal integrity, and enhanced durability.

To make this clearer, here’s a quick comparison table:

| Aspect | Basic PCB | Advanced PCB |

|---|---|---|

| Materials | FR4, aluminum | Ceramic, PTFE, copper-core, polyimide |

| Layer Count | 1-2 layers | 4+ layers (up to 64 or more) |

| Performance | Low to medium current/heat/speed | High current, superior thermal management, high-frequency signals |

| Cost | Low | Higher, but value-driven for complex needs |

| Applications | Toys, LED lights, simple consumer electronics | Smartphones, EVs, aerospace, medical devices |

| Complexity | Simple routing | Microvias, blind/buried vias, impedance control |

When should you opt for an advanced PCB? If your product requires miniaturization (like squeezing more components into less space), high reliability in harsh environments, or special properties like flexibility, that’s your cue. From our experience at JHYPCB, we’ve seen clients switch from basic to advanced PCBs and cut down on failures dramatically—take one automotive project where upgrading to a thick-copper design reduced overheating issues by 40%. It’s not about overkill; it’s about matching the board to the demands of your innovation.

In short, while basic PCBs keep the lights on for everyday tech, advanced PCBs power the future. If you’re wondering “advanced PCB vs basic PCB” for your next build, consider the long-term benefits—advanced options might cost more upfront but save you headaches down the line.

Types of Advanced PCBs: Exploring the Options

Now that we’ve covered the basics, let’s explore the various types of advanced PCBs. Each one is tailored to specific challenges, and at JHYPCB, we specialize in manufacturing them all with precision and care. Drawing from our ISO-certified facilities in China, we ensure every board meets global standards like RoHS, UL, and IPC Class 2/3. Here’s a rundown of the most common types, complete with their features, benefits, and where they shine.

1. Ceramic PCBs

Ceramic PCBs are the go-to for extreme conditions. Made from materials like alumina (Al₂O₃) or aluminum nitride (AlN), they offer unbeatable heat dissipation—up to 170 W/mK or more—and low thermal expansion, which prevents warping under high temperatures. They’re often single-layer for optimal yield and performance, but we can customize them using techniques like direct plated copper (DPC) or thick film.

Why choose them? If you’re dealing with power modules, RF applications, or high-temperature setups like in aerospace or industrial sensors, ceramics handle the heat without breaking a sweat. At JHYPCB, we’ve produced ceramic PCBs for clients in the defense sector, ensuring reliable operation even in rugged environments.

2. PTFE (Teflon) PCBs

For high-frequency wizards, PTFE PCBs are a game-changer. These use polytetrafluoroethylene (PTFE) with fillers like glass or ceramics to achieve low dielectric loss and stability at GHz-level signals—think up to 77GHz for radar systems. We offer them in 4 to 24 layers, with options for embedded antennas.

They’re ideal for aerospace, telecommunications, base stations, and military gear where signal integrity is critical. Imagine building a 5G antenna; PTFE ensures minimal loss, keeping data flowing fast and clear. Our team at JHYPCB has fine-tuned impedance control on these boards, helping clients meet stringent specs without rework.

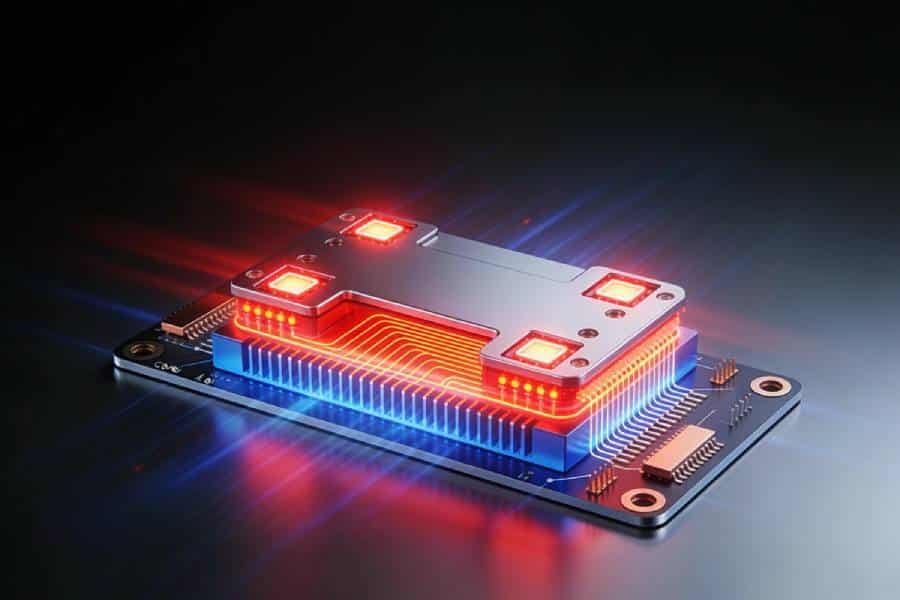

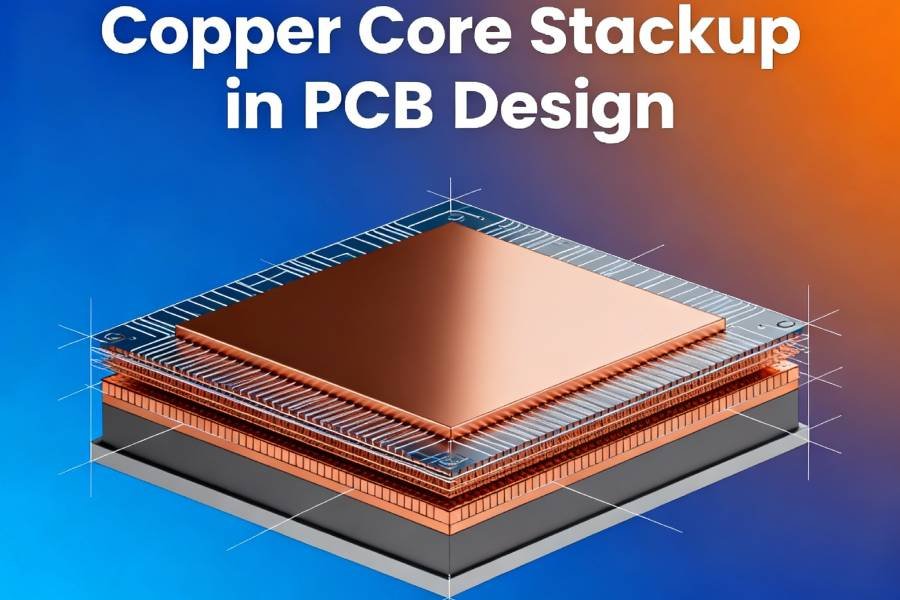

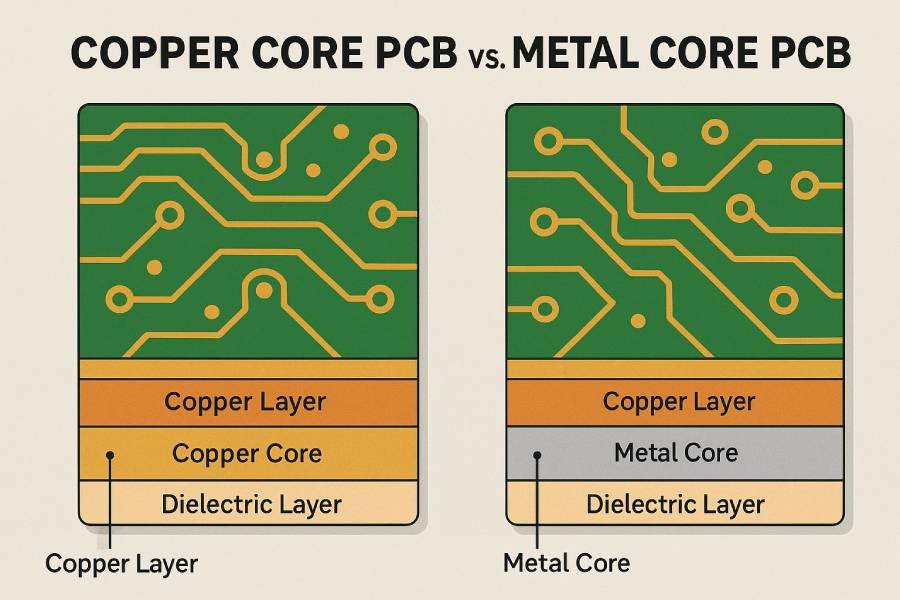

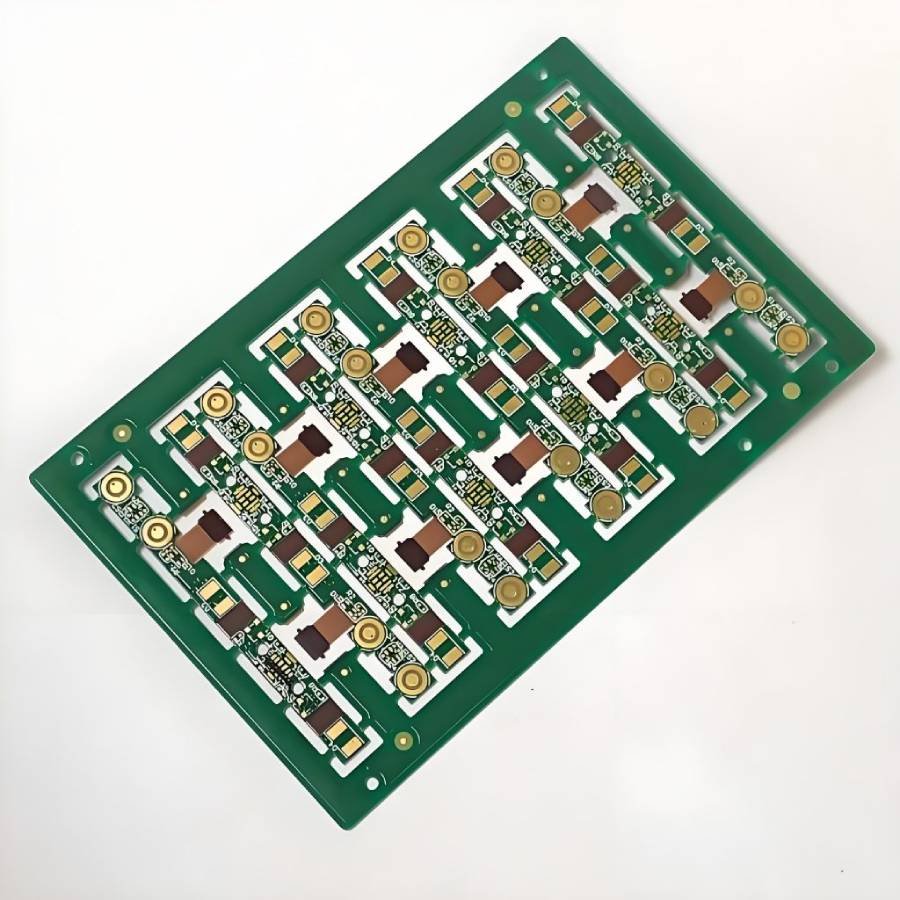

3. Copper-Core PCBs

When thermal management is key but you need something more robust than aluminum, copper-core PCBs step up. With a copper substrate providing conductivity up to 398 W/mK (especially with direct thermal paths), these are stars in high-power scenarios. We can make them in 1-8 layers, including thermoelectric separation designs.

Applications? Power electronics, automotive lighting, and industrial equipment love them for handling heavy currents without overheating. From our factory floor, a tip: Pairing copper-core with thick-copper traces can boost efficiency in EV chargers, something we’ve optimized for several global partners.

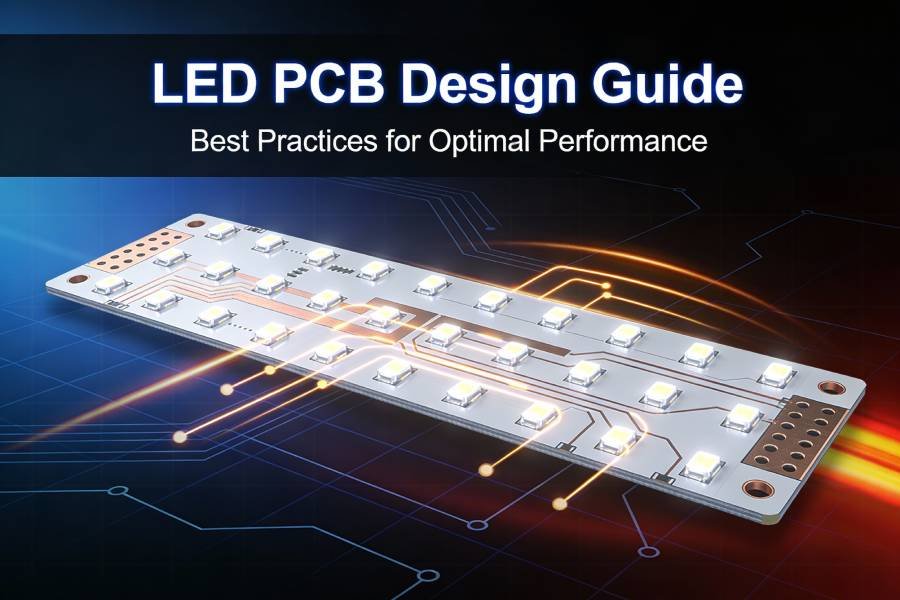

4. Flexible PCBs (FPCs)

Flexible PCBs, or FPCs, are all about adaptability. Built on polyimide or polyester substrates with rolled annealed (RA) or electrodeposited (ED) copper foil, they’re lightweight, bendable, and perfect for tight spaces. We provide 1-6 layer options, including transparent variants for specialized needs.

Wearables, medical probes, and compact consumer gadgets thrive on FPCs because they save space and weight while allowing 3D flexibility. Ever wondered how your smartwatch fits so much tech? Flexible PCBs make it possible. At JHYPCB, we ensure bending cycles meet your requirements, drawing from projects in the medical field.

5. Rigid-Flex PCBs

The best of both worlds: rigid-flex PCBs combine sturdy FR4 sections with flexible polyimide layers. We start with a flexible core, laminate FR4, and laser-remove excess for 2-24 layer designs. This hybrid reduces connectors, boosts reliability, and enables 3D assembly.

They’re essential in wearables, aerospace, medical implants, and military devices where space and durability matter. One client story from us: A rigid-flex design for a drone controller cut assembly time by 25%, proving how these boards streamline complex builds.

6. Multilayer FR4 PCBs

Don’t underestimate multilayer FR4—when layered up (4-40+), they become advanced powerhouses. By alternating prepreg and copper foil, then drilling plated through-holes, they support complex routing and high-speed signals.

Computers, communication systems, and industrial controllers rely on them for dense integration. At JHYPCB, our multilayer expertise includes high-layer counts with impeccable alignment, ensuring no signal crosstalk in high-speed servers.

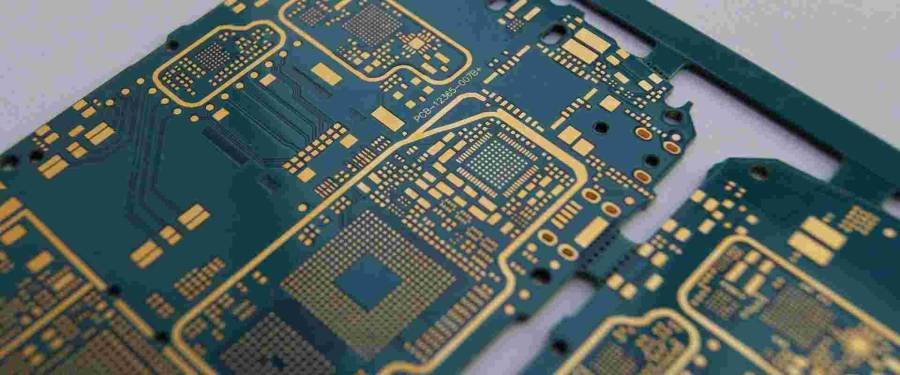

7. HDI (High-Density Interconnect) PCBs

For ultimate miniaturization, HDI PCBs use microvias, blind, and buried vias to pack more into less space. We offer 4-64 layers with fine lines (≤100 microns) and up to 20 connections per cm².

Smartphones, tablets, IoT devices, and servers need HDI for fine-pitch components like BGAs. It’s like Tetris for electronics—fitting everything perfectly. Our DFM analysis at JHYPCB helps optimize these for yield, as seen in our telecom projects.

8. Other Advanced PCBs

We also handle specialties like thick-copper (>3oz) for high-current power electronics, PCBs with busbars for extra conductivity, and embedded component designs to shrink footprints and enhance reliability. These are custom-tailored for automotive, industrial, and beyond.

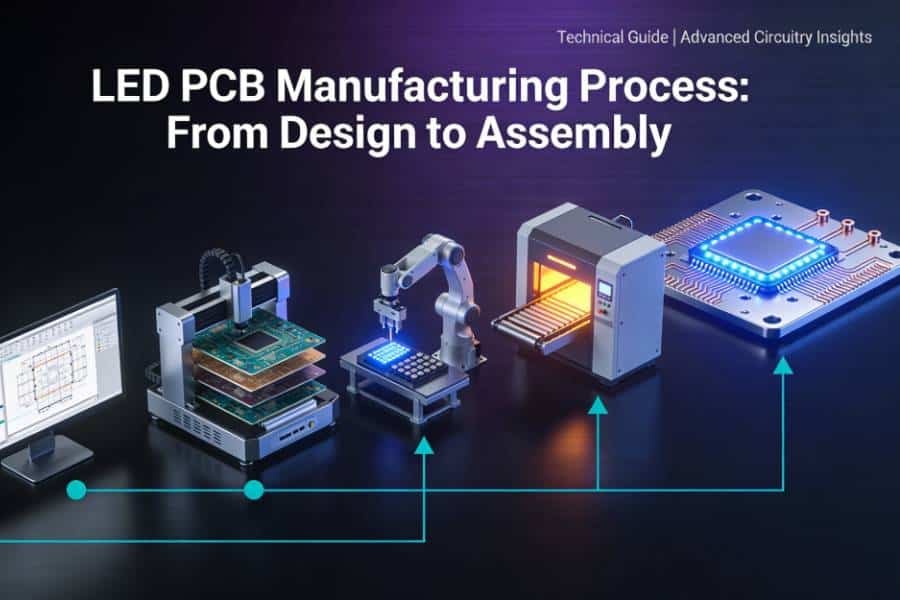

No matter the type, our advanced PCB manufacturing process includes strict controls for performance and longevity. If you’re pondering “types of advanced PCBs” for your project, reach out—we’ll guide you to the right fit.

Applications of Advanced PCBs in Modern Industries

Advanced PCBs aren’t just tech jargon; they’re the backbone of industries pushing boundaries. In aerospace and defense, ceramic and PTFE boards enable radar, avionics, and satellites to perform flawlessly in extreme conditions. Medical devices, like imaging systems or implants, lean on flexible and rigid-flex PCBs for precision and biocompatibility— we’ve supplied them for life-saving equipment.

Telecommunications, especially 5G, thrives on HDI and multilayer designs for low-loss, high-speed transmission. Automotive electronics? Copper-core and thick-copper PCBs power EV batteries, headlights, and controls, handling vibrations and heat. Industrial power systems use ceramics for converters and inverters, while consumer electronics—like your laptop or wearable—rely on HDI for compact, efficient performance.

Trends like IoT and EVs are fueling demand, requiring boards with multiple laminations, via-in-pad tech, and impedance control. At JHYPCB, a standout case was developing an HDI PCB for a medical wearable, boosting signal reliability by 30% and speeding up market entry.

In essence, advanced PCBs make cutting-edge tech possible, from high-frequency comms to robust power management.

Why Choose JHYPCB for Your Advanced PCB Needs?

If you’re ready to turn your ideas into reality, you need a partner who gets advanced PCB manufacturing inside out. That’s us at JHYPCB—your one-stop shop in China for high-quality fabrication and assembly. Since our founding, we’ve built two state-of-the-art facilities, delivering prototypes to mass production with affordability and precision.

Our edge? Free engineering support, including DFM analysis, stack-up design, and reliability testing. We’re certified to ISO 9001, IATF 16949, RoHS, REACH, UL, and IPC standards, ensuring every board is top-tier. Whether it’s component sourcing for turnkey assembly or custom SMT stencils, we handle it all.

We’ve served leaders in automotive, medical, telecom, and more, tackling projects like EV charging stations and radar systems. Quality is our promise, no matter the quantity.

To get started, email us at sales@pcbjhy.com with your Gerber files, BOM, and specs. We’ll provide a fast quote and expert advice to optimize your design.

Conclusion

Advanced PCBs represent the pinnacle of circuit board technology, offering the complexity and performance needed for today’s high-end applications. From ceramic wonders in aerospace to HDI marvels in smartphones, they drive innovation while ensuring reliability and efficiency.

At JHYPCB, we’re passionate about helping you navigate this world. With our expertise in advanced PCB manufacturing and assembly, you can confidently build the future. Ready to elevate your project? Drop us a line at sales@pcbjhy.com today—we’re here to make it happen.